Discussion on the cable production process: conductor twisting and twisting

: the process of twisting many small diameter monofilaments into a large cross-section conductive core according to certain rules.

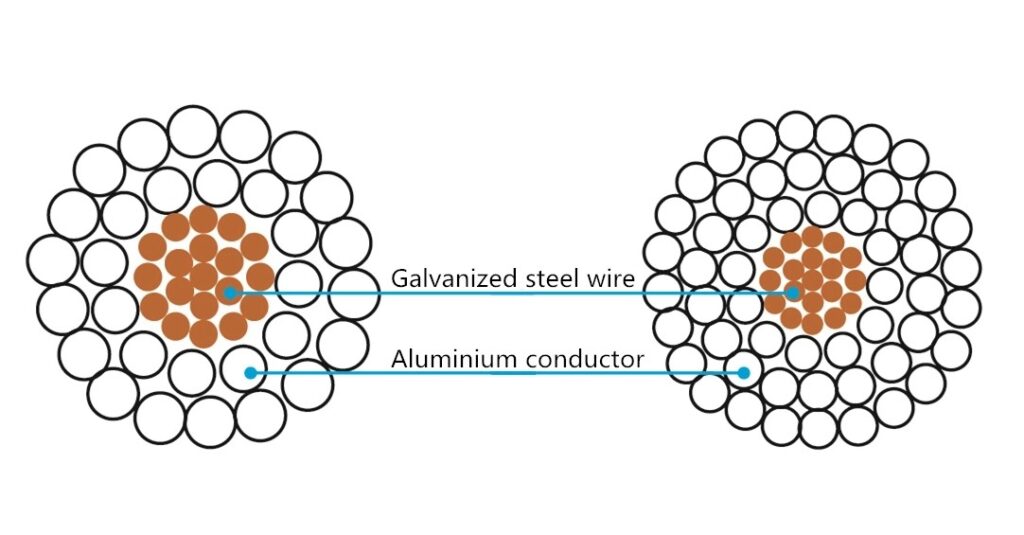

1. There are two types of twisted wires: normal twisted wires and irregular twisted AAC Cables.

Ordinary strands can be divided into ordinary concentric single stranded strands and ordinary concentric single stranded strands

(1) Ordinary stranded wire: single wires of the same diameter are twisted layer by layer according to concentric circles, and the direction of each layer is opposite.

(2) Combined stranded wire: made of a single wire of the same diameter, different materials or different diameters and different materials (representative products (such as overhead conductors))

Ordinary concentric stranded wire: a multi-stranded ordinary stranded wire or bundle Stranded wire concentrically stranded.

Irregular stranding (strand): strands formed by multiple single strands in the same direction, which does not comply with the law of twisting. The positions of the single strands are not fixed to each other, and the shape of the strands is difficult to maintain Round.

2. The biggest difference between the bundle wire and the ordinary stranded wire is that each single wire of the ordinary stranded wire has a fixed position and is regularly twisted layer by layer. There is no fixed position between the single wires of the bundle According to the law of twisting, the position will not be twisted together.

3. The characteristics of irregular twisting (bundling) : Since each single wire in the bundle is twisted in one direction, there is a residual amount of sliding between each single wire during bending. The amount is large and the bending resistance is small, so the bending performance of the bundle is particularly good. For wire and cable products that need to be flexible and frequently moved, the wire bundle is used as the conductor core.

4. The characteristics of the stranded core:

(1) Flexibility Good; by using a core composed of several single wires with smaller diameters, the bending resistance of the cable can be improved, and the processing, manufacturing, installation and laying of the wires and cables are convenient.

(2) Good stability; the core is It is composed of multiple single wires twisted according to a certain direction and twisting rules, because each single stranded wire is located in the stretched area above the twisted wire in the twisted wire, and is located in the lower compressed area When the stranded wire is bent in sequence, the stranded wire will not be deformed.

(3) Good reliability; due to material inhomogeneity or defects in twisting, using a single wire as the cable and the conductor of the cable easily affects the reliability of the conductor core. The defects of the conductor core formed by multiple single wires are scattered and will not be concentrated on a certain point of the conductor, so the reliability of the conductor core is much stronger.

(4) High strength; the strength of the single-stranded core is higher than that of the single-stranded core.

5. Explanation of terms:

5. Explanation of terms:

(1) Pitch: the distance that a single filament advances one circle along the axis.

(2) Pitch diameter ratio: the ratio of the pitch length to the strand diameter.

(3) The relationship between the pitch and the flexibility of the strands: the smaller the pitch, the better the flexibility of the strands; on the contrary, the larger the spacing, the worse the flexibility of the strands.

(4) Stranding factor: the ratio of the actual length of a single wire to the pitch length in the pitch of the twisted wire.

(5) Twisting direction of the stranded wire: right direction (z direction) left direction (s direction)

(6) Compact conductor: common compact conductors are compact round, sector and compact tile-shaped (five-core cables) Semi-circular (two-core cable)

6. Compression purpose:

(1) Compact sector conductor: reduce the outer diameter of the cable, save product costs, and reduce the weight of the cable.

(2) Compact circular conductor: Improve the surface quality of the stranded conductor, reduce the diameter of the conductor, and increase the filling factor of the conductor. The compacted conductor surface is smooth without burrs, and the electric field on the conductor surface is uniform. Save materials and reduce costs (to learn more about cable technology, please click here. A lot of dry goods are waiting for your visit.)

7. Conductor classification:

According to GB/t3956 “Cable Conductor”, there are four types of conductors, namely the first One, the second, the fifth and the sixth. The first is a solid conductor, and the second is a stranded conductor, both of which are suitable for fixed laying of cables. The fifth and sixth types are stranded conductors, which are used for flexible cables and cords. The sixth is softer than the fifth.

For more information on cables, click Joy ’cable Blog