Everything You Need to Know About H32 5083 Aluminum Sheet

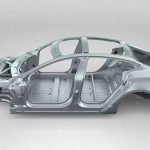

H32 5083 aluminum sheet is a type of aluminum alloy that is commonly used in various industries such as marine, aerospace, automotive, and construction. In this article, we will provide a comprehensive guide to H32 5083 aluminum sheet, including its properties, applications, advantages, and manufacturing process. Properties of H32 5083 Aluminum Sheet H32 5083 aluminum … Read more