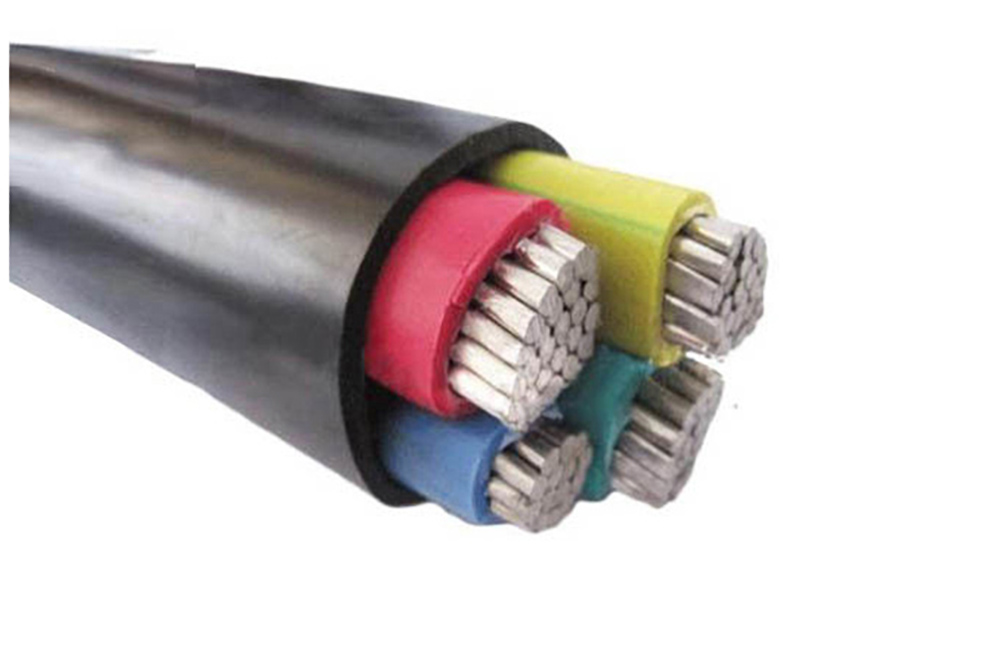

1. Wire drawing and twisting

Qualified products are not detected, but manufactured. For the control of 110kv cable eccentricity, each department in the cable enterprise has corresponding quality control responsibilities. Here we mainly talk about the understanding and detailed control of conductor preparation and tooling level. When designing a conductor, people give priority to or often only consider the reference conductor carrying capacity and conductor DC resistance. This is not enough for 110kv and above power cables. The roundness and straightness of the conductor often affect the XLPE insulation material. Distribution, which in turn affects the electric field distribution in the cable; the monofilament ductility of the conductor filaments will affect the cable insulation stress; the conductor surface quality (such as oxidation caused by improper storage, conductor knocks in the disk flow, etc.) on the current carrying capacity Wait. In the process of drawing, if the concentration and temperature of the emulsion are not regularly checked and replaced according to the standard, it is very likely that the monofilament will be oxidized in the drawing. In the conductor stranding process, the conductor protection is insufficient. Some companies have installed online DC resistance measuring instruments but do not use them. Some companies produce high-voltage cables according to the habit of producing low- and medium-voltage cables, even when they are producing 110kv cables because of the absence of staff on duty. , The personnel are transferred from the production line of low-voltage cables. These ideological understanding and detailed control will seriously affect the eccentricity control of the cable, but they are often ignored due to people’s experience. Uneven cable field strength distribution caused by scratches is an undesirable result.

2. Preservation and scientific use of insulating materials (including insulation, conductor shielding, and insulating shielding)

The transportation, storage and use of 110kv XLPE insulation material have strict requirements. The XLPE transportation link is not controlled by the cable company but is controlled by the cable material supplier. However, the cable company should also put forward corresponding requirements. The climate in the south is humid (install indoor temperature control equipment, balance humidity and temperature, and store cable materials at room temperature) and so on. When cable companies store XLPE cable materials, they should make unified arrangements and establish special insulation materials and shielding materials storage rooms to prevent material deterioration or abnormalities caused by climate change. There are only a handful of cable material companies in China that produce 110kv and above. Most of the ultra-high voltage XLPE insulation materials are imported from Borealis, Dow Chemical and other foreign companies. Due to language differences, most of the materials’ certificates are in English, and there is no Obvious production date and shelf life identification, using codes or codes that only cable material manufacturers can understand, this brings great inconvenience to cable material users. When the cable material is used in batches, the most contacted cable material is Workshop operators rarely understand English. The author had previously suggested a cable material foreign company, but only got a vague answer. This is because UHV cable materials belong to the seller’s market and are monopolized by a few companies. It is recommended that domestic cable companies must clarify the transportation conditions, production date, shelf life and Chinese-English bilingual instructions when purchasing UHV cable materials. In addition, XLPE insulation, shielding material storage rooms and inter-connection operation rooms should be prohibited from entering and exiting non-duty operators as much as possible. When there are special circumstances, dust removal work must be done to avoid cable breakdown due to a strand of hair. If conditions permit, companies can install monitors in the storage room to increase assessment efforts so that all employees can realize the huge impact of high-voltage and ultra-high-voltage insulation materials on cables.

3. Process technology

The XLPE insulated cable cross-linking production line in the cable industry in the world basically has two methods: catenary and tower. In recent years, the discussion of which is better for catenary and tower has been going on. According to public information, if China Nearly 60 vertical towers have all cross-linked lines in full production, which can meet the world’s demand for high-voltage and ultra-high-voltage cables. Therefore, the 21st order of the Development and Reform Commission in 2013 on the addition of 6KV and above dry-type cross-linking production lines to the cable industry limits.

The technical factors that affect the eccentricity of the cable insulation also include: the specifications of the extrusion die, the stress of the XLPE insulating material, the operating temperature and speed of the cross-line, the skill level of the operators, and so on.For more cable knowledge, please follow Chris’s cable.