1. Bare wire and bare conductor products

The main features of this class of products are: pure conductor metal, no insulation and sheath layer, such as steel-cored aluminum strand wire, copper-aluminum busbar, electric locomotive wire; The processing technology is mainly pressure processing, such as melting, rolling, drawing, stranded/pressed stranded, etc. Products are mainly used in suburbs, rural areas, user lines, switch cabinets and so on.

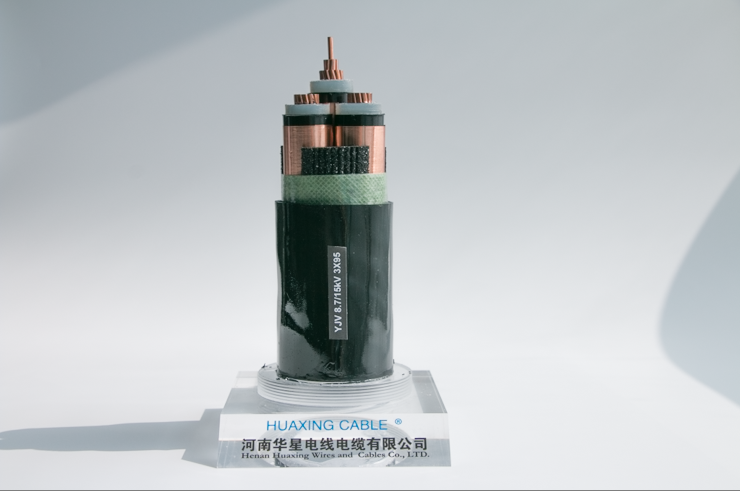

2. Power cables

The main features of this class of products are: extruded (wound) outer conductor covering insulation layer, such as overhead insulated cables, or twisted several cores (corresponding to the phase, zero and ground wires of the power system), such as overhead insulated cables with more than two cores, or additional sheath layer, such as plastic/rubber sheathed wires and cables. The main technologies are drawing, stranding, insulation extruding (wrapping), cabling, armor, sheath extruding, etc. The different process combinations of various products are different to some degree.

The products are mainly used in the transmission of strong electric energy in the power lines of generation, distribution, transmission, transformation and power supply, with large current (tens to thousands of amps) and high voltage (220V to 500kV and above).

3. Wires and cables for electrical equipment

Such products, the main characteristics are: various specifications, application range, use voltage in 1 kv and below is more, to derive new products constantly, in the face of special occasions, such as fireproof cables, flame retardant cable, low smoke zero halogen/against termites, low smoke low halogen cable, mouse cable, oil/cold/heat resistance, abrasion resistance cable, medical/farm/mining cable, thin wire, etc.

4. Communication cable and optical fiber (brief introduction)

With the rapid development of the communication industry in the past twenty years, the products have also developed at an amazing speed. From the past simple telephone and telegraph cables to thousands of pairs of voice cables, coaxial cables, optical cables, data cables, and even combined communication cables.

The structure size of this kind of product is usually small and uniform, and the manufacturing precision is high.

5. Electromagnetic wire (winding wire)

Mainly used for all kinds of motors, instruments and meters.

A derivative/new product of wire and cable

The derivative/new products of wires and cables are mainly produced by adopting new materials, special materials, changing product structure, improving process requirements, or combining different kinds of products due to different application occasions, different application requirements, convenience of equipment and reducing equipment cost.

Use different materials such as flame retardant cable, low smoke halogen-free/low smoke halogen-free cable, termite proof, mouse proof cable, oil/cold/temperature resistant cable, etc.

Change product structure such as: fire-resistant cable, etc.

Improve the process requirements such as: medical cable;

Combined products such as OPGW, etc.

Easy to install and reduce equipment cost such as: prefabricated branch cable.