The temperature of the cable is closely related to the load, but only checking the load can not ensure that the AAAC Cable is not overheated

(1) the thermal resistance coefficient and side-by-side correction coefficient used in calculating the allowable ampacity of cables may be different from the actual situation.

(2) when choosing cables to determine conductor cross-sectional area, designers may lack sufficient information about the laying conditions and surrounding environment of the whole line.

(3) newly built and rebuilt power lines or thermal pipelines have an impact on the original surrounding environment and heat dissipation conditions.

(4) the excessive density of cables greatly exceeds the regulations of design and operation departments. In addition to measuring the load frequently, the operation Department must also check the actual temperature of the cable surface to determine whether the AAC Cable is overheated. The inspection shall be carried out at the maximum load and the section with the worst heat dissipation condition (generally not less than 10m). Thermocouple or pressure thermometer can be used for measuring instrument. The pressure thermometer is easy to install. Two temperature measuring points shall be installed at each measuring point. When measuring the temperature of the cable, the temperature of the surrounding environment should be measured at the same time, but it must be noted that the temperature measuring point of the surrounding environment should be kept a certain distance from the cable (generally 3M away), and there is no influence of external heat source.

On site detection method

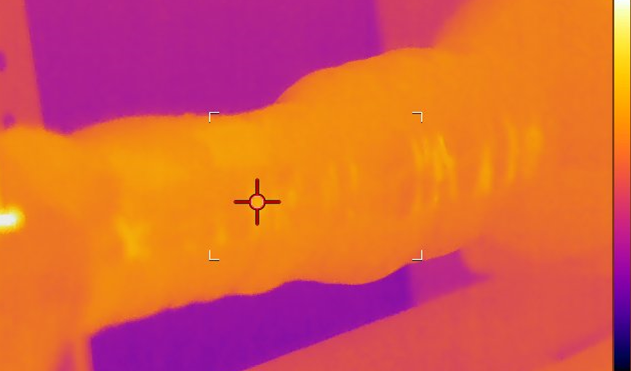

During infrared detection, the cable should be live running for more than 24 hours, and try to remove or avoid the shelter between the cable and the thermometer, such as glass window, door or cover plate, etc; It is necessary to measure all parts of the cable line to avoid missing the measuring parts; It is best to carry out the test in the peak load state of the equipment, generally no less than 30% of the rated load. The infrared detection of the arrester connected with the cable terminal can refer to the requirements of DL / t664.

a) The emissivity of the tested equipment should be selected correctly, especially considering the influence of metal material oxidation on the selection of emissivity. For the selection of emissivity, please refer to Appendix B; Generally, 0.9 for metal conductor and 0.92 for insulator;

b) If the safety distance is allowed, the infrared instrument should be close to the equipment under test as far as possible, so that the equipment under test can fill the field of view of the whole instrument, so as to improve the resolution and temperature measurement accuracy of the instrument to the surface details of the equipment under test. If necessary, medium and long focal length lenses should be used; Generally, medium and long focal length lenses are used for outdoor terminal detection;

c) The compensation parameters such as atmospheric temperature, relative humidity and measurement distance are input and corrected, and the appropriate temperature range is selected;

d) Generally, the infrared thermal imager is used to scan all the tested parts, focusing on the cable terminal and intermediate connector, cross interconnect box, grounding box, metal sleeve grounding point and other parts. After finding the abnormal parts of the thermal image, the abnormal parts and the key tested equipment are measured in detail;

e) In order to measure temperature accurately or track conveniently, several different directions and angles should be set in advance to determine the best detection position and mark it for future retest, so as to improve the comparability and work efficiency;

f) Record the actual load current and voltage of the tested equipment, the temperature of the tested object and the temperature value of the environmental reference body according to the format of Appendix C.

For more information on cables, click Joy ’cable Blog