In recent years, the city has developed rapidly

Subway, station, hospital, school, high-rise residence

Expansion of public facilities construction scale

The number of high-rise buildings surged

The demand for urban electricity is rising

Such a densely populated key area

In case of fire, the consequences are serious

In recent years, the fire spread trend in such places shows a similar pattern

According to the analysis of construction safety and fire protection experts

At present, there are still many cables selected for public facilities

No fire resistance

It is difficult to play its due role in fire

The law expressly stipulates that China’s civil construction law stipulates that in the code for fire protection design of construction projects, the fire protection system needs to use mineral insulated cables in order to pass the fire protection acceptance.

Under fire conditions, mineral insulated AAAC Cable can not only ensure the fire power supply within the fire duration (more than 180 minutes), but also will not delay combustion, produce smoke and secondary disasters, so as to win valuable time for fire rescue.

It can be said that mineral insulated cable is a special cable that must be used for fire protection in national important facility construction, large public areas, high-rise buildings and other places. Its fire resistance, durability, safety, reliability and economy can not be replaced by traditional power cable.

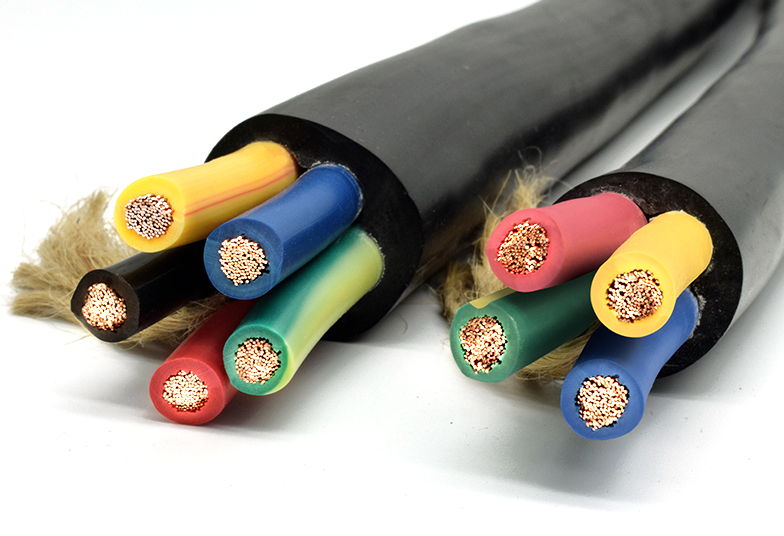

1、 Mineral insulated cable structure

Chengtiantai mineral insulated cable is a kind of cable that uses copper sheath to wrap copper conductor core wire and magnesium oxide powder as inorganic insulating material to isolate conductor and sheath (outer sheath is optional), forming a close whole with metal core and sheath.

Magnesium oxide is also a non combustible material, and will not produce toxic smoke or other harmful substances when encountering high temperature. Therefore, the cable with magnesium oxide as the insulator of copper core and copper sheath has good performance and many advantages.

2、 Performance and advantages of mineral insulated ACSR Cable

Chengtiantai mineral insulated cable mainly includes bbtrz (flexible mineral insulated fireproof cable) and yttw (flexible inorganic mineral insulated cable) series. It has the characteristics of good fire resistance, high temperature resistance, large current carrying capacity, waterproof, corrosion resistance, mechanical damage resistance, radiation resistance, electromagnetic compatibility and elegant appearance. At the same time, the cable will not emit any smoke under fire conditions Halogen and toxic and harmful gases.

1. Fire performance

Because mineral cables are all composed of inorganic substances, they will not cause fire, can not burn or support combustion, and will not produce toxic gases. Even if there is external flame combustion, the cable can still work normally. Mineral insulated cable is insulated with magnesium oxide, and the melting point of magnesium oxide is as high as 2800 ℃, which is difficult to burn easily. Therefore, the fire resistance of mineral insulated cable is excellent.

The test shows that the mineral insulated cable can run normally after burning in the flame with the temperature up to 800 ℃ – 900 ℃ for 2h; After burning under 1000 ℃ flame for 30 min, the cable is still intact and continues to operate normally.

2. High temperature resistant operation, large current carrying capacity

The normal service temperature of mineral insulated ACAR Cable can reach 250 ℃. Under special circumstances, the cable can maintain operation for a short time at a temperature close to the melting point of copper sheath. It is very suitable for laying in high temperature places, such as metallurgy, boiler, glass furnace, blast furnace and so on.

Its cut-off flow is much higher than that of other cables. Because magnesia powder has a better conductor coefficient than plastic, the cut-off flow is greater at the same working temperature. For lines above 16mm, one section can be reduced, and two sections can be reduced where people are not allowed to touch.

3. Waterproof, explosion-proof, high mechanical strength

The insulating layer of mineral insulated cable is processed by high-density compaction process, and then protected by seamless copper sheath. In the product standard, it must meet the three requirements of fire resistance, spray resistance and mechanical impact, and can withstand severe impact and mechanical damage. Therefore, it can not only prevent the infringement of water, moisture, oil and some chemical substances, but also apply to the connection of various explosion-proof equipment and equipment in places with explosion risk.

4. Overload protection

When the line is overloaded, the plastic cable will cause insulation heating or breakdown due to overcurrent or overvoltage. For mineral insulated cables, as long as the heating cannot reach the melting point temperature of copper, the cable will not be damaged. Even if the breakdown occurs instantaneously, the magnesium oxide at the breakdown point will not form carbide at high temperature. After the overload is cleared, the cable performance will not change and can still continue to be used normally.

5. The service life is longer and more safe and reliable

Since the structure of mineral insulated cable is composed of copper core and insulating sheath, which is a closed whole, it is difficult for the material to be aged due to the action of oxygen in the external air, which makes the overall service life of the cable longer (2-3 times the service life of ordinary cables). In addition, the characteristics of the copper sheath make the grounding of the cable better, Therefore, lightning protection and grounding measures are effectively realized, so as to ensure the safe and reliable operation of electrical lines.

Due to many excellent characteristics of mineral insulated cables, they have been successively adopted by many domestic electrical design codes or standards in recent years, and also used in many engineering projects in different industries. It can be expected that the use of mineral insulated cables in China will increase significantly in the next decade.