Outer sheath is a protective covering covering the cable sheath (inner sheath), mainly used for mechanical strengthening and anti-corrosion. Common cables have inner sheath as the outer sheath of metal sheath and inner sheath as the outer sheath of plastic sheath.

The outer sheath of the metal sheath is generally composed of three parts: the liner layer, the armor layer and the outer quilt layer. The gasket layer is located between the metal sheath and armor layer, which plays a role of protecting gasket and metal sheath against corrosion. The armor layer is metal belt or metal wire, mainly for mechanical protection, the metal wire can withstand the tension. The metal armor is protected from corrosion by the outer layer. The cushion and outer layer of the village are composed of asphalt, polyethylene tape, impregnated paper, PVC or polyethylene sheath and other materials. According to the different use environment and conditions of various cables, its outer sheath structure is also different, the outer sheath structure of common various types of power cables are shown in the table of various types of cables.

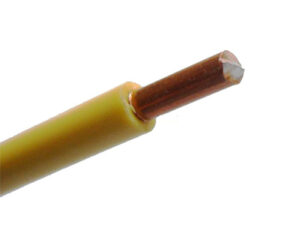

There are two kinds of structure of outer sheath for plastic sheath. One is only PVC or polyethylene sheath without outer sheath. The other is PVC sheath extruding PVC sheath or polyethylene sheath with the same thickness as the inner sheath. Traditional PVC outer sheath Due to the low working temperature of PVC, high voltage crosslinked polyethylene (XLPE) cable with high operating temperature and protective insulation requirements is not suitable, so now high density polyethylene (CHDPE) or low density polyethylene (LLDPE) as the outer sheath has been very common, but no flame retardant. Fire prevention measures or flame retardant cables should be taken when laying. Using HDPE as the outer sheath can improve the insulation level of the sheath. The outer sheath and the corrugated metal sheath should be bonded.