After the cable line breaks down (including the breakdown during preventive test), it must be repaired immediately to avoid a large amount of water invading and expanding the scope of damage.

The elimination of faults must be thorough and clean. Otherwise, although it can be used after repair, it will still cause faults in the future, resulting in repeated repair and greater losses.

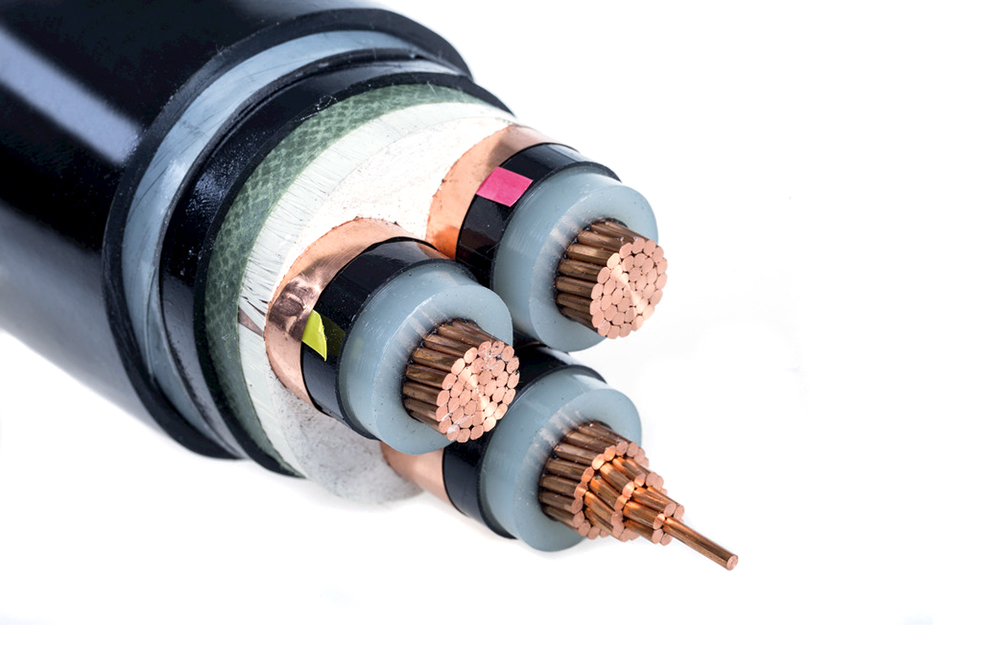

to repair the fault, the damp part of the ACSR Cable must be removed, and the insulating agent or insulating layer must be checked for carbonization. This paper introduces several simple fault repair methods.

(1) single phase grounding of cable line (without tripping): the conductor damage caused by this kind of fault cable may be local. If it is a mechanical damage, only the AAC Cable insulation is damaged, the conductor is slightly singed, and the land near the fault point is relatively dry, it can generally be repaired locally. The cable core can not be sawed off, only the damaged part of the conductor can be treated smoothly, and the insulation can be wrapped and sealed.

(2) breakdown of cable joint in preventive test: because the voltage of preventive test is high and the insulation strength of the joint decreases gradually during operation, such faults often do not make the ACAR Cable subject to water intrusion. In this case, the connector can be disassembled to check whether the cable conductor is intact and whether the insulation is damp. Check 1 ~ 2 layers of insulating paper on the peelable surface of the oil paper cable, wash with hot oil, and completely remove the moisture if any.

(3) if the indoor cable terminal is broken down in the pre-test, it can also be disassembled and partially repaired. The process is similar to reinstallation, but requires moisture removal. Generally, there is some residual wire left at the terminal part, so the sheath can be appropriately cut for another section, and the operation is more convenient than dismantling the joint.