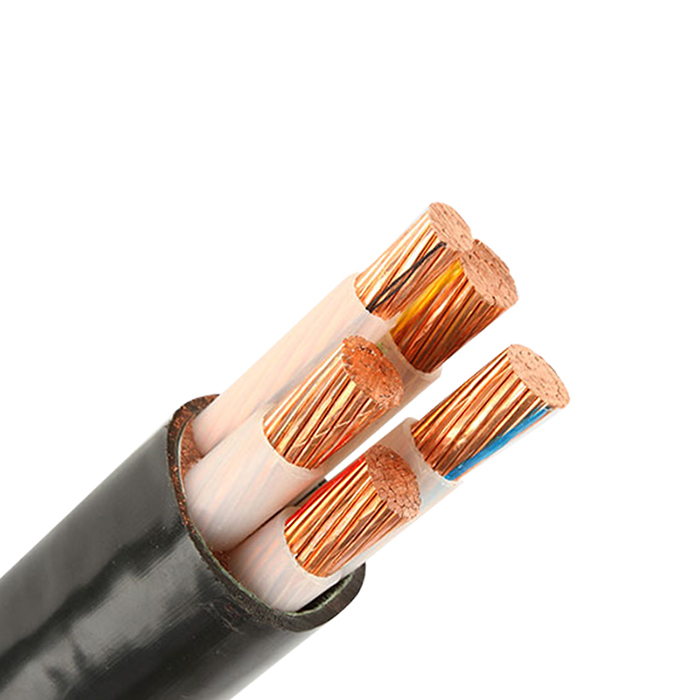

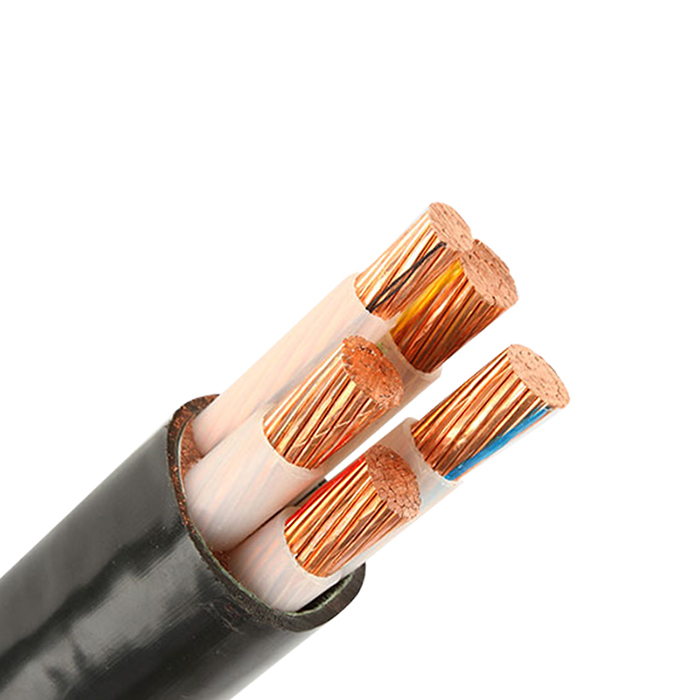

In recent years, silane cross-linked polyethylene cable material (hereinafter referred to as XLPE) has become the leading material for low-voltage cross-linked (xlpe) insulated cable insulation because of its simple manufacturing equipment, mature technology, convenient operation, and low overall cost.

At present, the commonly used XLPE is the two-step XLPE. When the cable factory produces the insulated core, the polyethylene (PE) grafted with silane and the catalyst masterbatch are mixed in a certain proportion and extruded in a common extruder. Then the cross-linking is completed in hot water or steam; another one-step method XLPE is made by the cable material manufacturer, which mixes all the raw materials together in a special method according to the ratio, and the cable factory directly completes the grafting and grafting in one step in the extruder. Extrude the insulated core, and then complete the cross-linking under natural conditions. The common point of these two types of XLPE is that no special extrusion equipment is needed, and the cross-linking process is relatively simple. As long as the raw materials and process conditions meet the requirements, it can be made into an insoluble and infusible thermosetting plastic. Compared with thermoplastic PE, its heat-resistant deformation and mechanical properties at high temperature, environmental stress cracking, aging resistance, chemical resistance, etc. have been improved or improved, while the electrical properties remain basically unchanged, and the long-term work of the cable The temperature is increased from the original 70°C to 90°C, thereby improving the short-term current withstand capability of the cable. In summary, XLPE low voltage cables have become the main products of cable manufacturers in recent years.

As a third-party inspection agency, the type of cables inspected is increasing year by year. How to accurately provide the test results of the thermal extension and aging performance of this type of product? Inspectors are faced with some special circumstances. The following is an analysis:

First, the problem of abnormal thermal extension of XLPE insulation. When testing, the author often finds that the elongation rate of XLPE cable insulation under load in the 200℃ thermal extension test greatly exceeds the requirements of the standard, or the sample is put into the oven and melted in a short time. If the test is repeated immediately with the original sample, The reproducibility of the results is very good. If you follow the routine, as long as the test method is correct and the sampling is correct, a conclusion can be drawn based on the test results. However, for XLPE, doing so may be very risky. Because the cross-linking process of XLPE is a slow chemical change process related to temperature, humidity, time, insulation thickness and other factors, especially the naturally cross-linked XLPE insulation material is affected by the above factors to complete the cross-linking. There will be a big difference in time, and it is entirely possible that the natural cross-linking has not been completed within the prescribed test period. Once the natural cross-linking is completed over time, its performance may meet the requirements of national standards. For such cases, the author believes that under the premise of reflecting the current situation of the sample, we should not rush to determine, but should provide the sample with a condition to promote crosslinking-soaking in hot water at 90°C±2°C Do the hot extension test after 4 to 5 hours. Practice has proved that the test results at this time can be used as a basis for judgment. It is worth mentioning that individual manufacturers are pursuing commercial profits one-sidedly, using the similar characteristics of PE and XLPE to pretend to be XLPE, and PE cable will not produce cross-linking changes no matter what conditions are provided to promote cross-linking. In terms of performance, it does not meet the requirements of XLPE at all. This is the same reason that rocks cannot hatch chicks. This requires inspectors to have the ability to identify true and false, good and bad XLPE. In fact, through observation and work accumulation, we can distinguish whether the tested sample is under-crosslinked, inferior XLPE or PE is used according to the fusing time and fusing point of the sample after it is placed in the oven. However, as a third-party inspector, you cannot draw conclusions based on experience alone, and must make judgments based on real data.

Second, the problem of the change rate of XLPE heat aging test exceeding the standard. During testing, if you get the sample, prepare it immediately, and put it in the oven for aging as usual, the tensile strength and elongation at break will often exceed the standard after aging, and you must be cautious in judging this result. This phenomenon is not completely caused by poor aging performance, it may be because XLPE has not been completely cross-linked (from the time curve of XLPE cable material thermal elongation with warm water, it can be seen that when the thermal elongation is qualified, it does not represent the sample Completely cross-linked), and after being put into the aging box, XLPE is still completing its cross-linking process, which leads to an increase in tensile strength, a decrease in elongation at break, and a final change rate exceeding the standard. Due to the long time to complete the aging, it will be troublesome to discover the problem once the test is over. Therefore, it is necessary to thoroughly crosslink the sample before performing the aging test.

In summary, it can be seen that special factors should be considered to determine the thermal elongation and thermal aging performance of XLPE. Personnel engaged in third-party inspections can neither make a hasty conclusion about the test results, because doing so will risk misjudgeting qualified products as unqualified; nor can they avoid these two tests because it is difficult to draw conclusions. This may cause substandard products or counterfeit products to be missed. Therefore, it is necessary to exclude the possibility that the sample has not been cross-linked or completely cross-linked before performing the above two tests. We advocate the use of scientific and reasonable test methods to provide fair and reliable test results.