1. Fire-resistant cable

On the basis of improving the manufacturing process of the refractory layer and adding the refractory layer, the Class A refractory cable has been developed. It can withstand combustion for at least 90 minutes in a flame at 950℃~1000℃ and at a rated voltage without the cable being broken down ( That is, the 3A fuse does not blow).

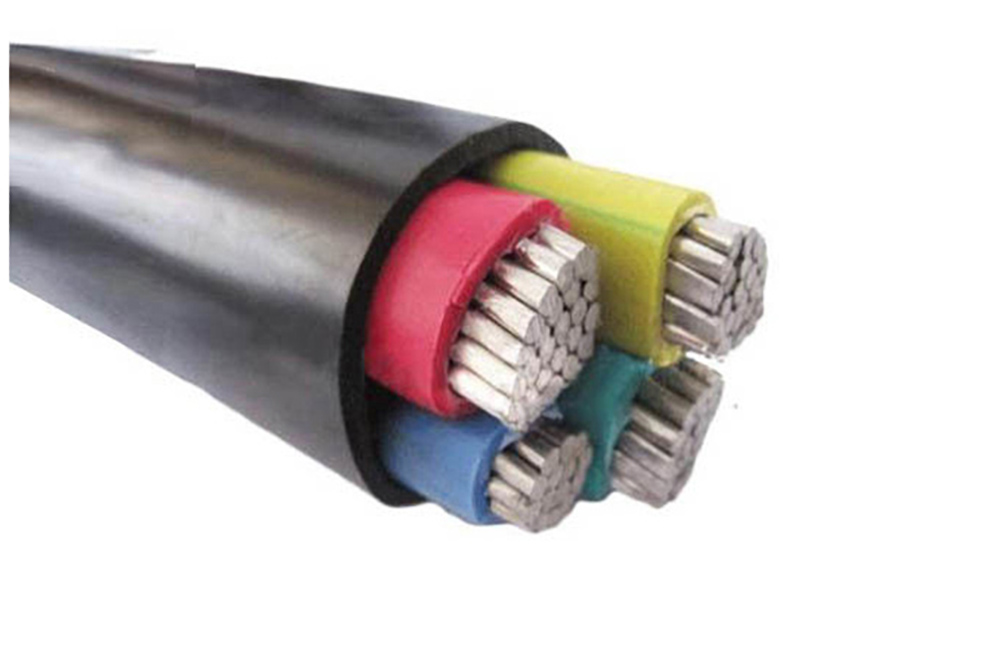

2. Flame-retardant cable

Flame-retardant cable is a kind of fire-resistant cable with better performance. It is processed by copper core, copper sheath, and magnesium oxide insulation material, referred to as MI cable.

The cable is completely composed of inorganic materials as the fire-resistant layer, while the fire-resistant layer of the ordinary fire-resistant cable is composed of inorganic and general organic materials. Therefore, the MI cable has better fire resistance than ordinary fire-resistant cables and will not decompose due to combustion to produce corrosiveness. gas.

MI cable has good fire resistance characteristics and can work at a high temperature of 250 ℃ for a long time. At the same time, it also has explosion-proof, strong corrosion resistance, large current carrying capacity, radiation resistance, high mechanical strength, small size, light weight, long life, and smokeless specialty.

However, the price is expensive, the process is complicated, and the construction is difficult. In oil-irrigated areas, important wooden public buildings, high-temperature places and other occasions with high fire resistance requirements and acceptable economic efficiency, this kind of cable with good fire resistance can be used.

Note: Fire-resistant cables can maintain normal power supply for a period of time when a fire occurs, but flame-retardant cables do not have this feature

Three, the problems that should be paid attention to when designing and applying

1. When fire-resistant cables are used in cable tunnels, cable interlayers with dense cables, or in flammable places such as oil pipes, oil depots, etc., Class A fire-resistant cables should be selected first. In addition to the above cases and when the number of cables is small, Class B fire-resistant cables can be used.

2. Fire-resistant cables are mostly used as power supply circuits for emergency power supplies, which require normal operation in the event of a fire. As the ambient temperature rises sharply during a fire, in order to ensure the transmission capacity of the line and reduce the voltage drop, for circuits with long power supply lines and strictly limited allowable voltage drops, the cross-section of the fire-resistant cable should be enlarged by at least one level.

3. Fire-resistant cables cannot be used as high-temperature cables.

4. In order to reduce the failure probability of cable joints in fire accidents, the number of joints should be reduced as much as possible during installation to ensure that the lines can work normally in a fire. If branch wiring is needed, fire-proof the joints should be done.