The structure of mineral insulated ABC Cables with different names is convenient for us to design and select better, and there is no confusion about many naming rules.

What are (rigidity) and (flexibility)? For a long time, the domestic mineral insulated cables are divided into two types: rigidity and flexibility.

The internationally used magnesium oxide mineral insulated cable (IEC 60702-1:2002) uses copper solid conductor instead of stranded conductor or soft conductor which is used in our common common cable.

Later, the following MI cables were developed by domestic production enterprises:

(1) It meets the industry standard: yttw series of jg/t 313 metal sheathed inorganic mineral insulated cable and terminal with rated voltage of 0.6/1kv and below (the release and update time of the standard is 2011 and 2014);

(2) It meets national standards: RTT series of gb/t 34926 mica tape mineral insulated corrugated copper sheath cable and terminal with rated voltage of 0.6/1kv and below (the standard release time is 2017);

(3) There are also some mica tape mineral insulated cables that meet the enterprise standards: non solid conductor.

All the above cables are generally classified into flexible mineral insulated cables in the industry, only to distinguish them from rigid MgO mineral insulated AAC Cables.

1. What form of (MI) cable is identified by the specification

The code for fire protection design of buildings GB 50016-2014, article 10.1.10 of the article description states that:

Mineral insulation non combustible cable is composed of copper core, mineral insulation material, copper and other metal sheath. Besides good conductivity, mechanical and physical properties and fire resistance, it also has good non flammability. Under fire conditions, this cable can ensure the fire power consumption within the fire duration.

That is to say, mineral insulation cable recognized by the specification must be made up of copper core, mineral insulation material, copper and other metal sheath as the basic composition.

BTT series rigid mineral insulated cable structure form

According to this requirement, we will see whether the structural forms of various rigid cables and flexible cables meet the requirements.

2. Rigid cable with unique naming rule (BTT)

BTT series mineral insulated cable is the only mineral insulated cable recognized internationally. It is a kind of cable with seamless copper tube sheath and dense compacted magnesium oxide crystal powder in the middle as the insulation material. The conductor is a single copper rod cable.

The reason for being recognized internationally depends on the material used is the real high temperature resistant material, among which the melting point of copper conductor and copper sheath is 1083 ℃, and the melting point of MgO mineral insulation layer reaches 2800 ℃, so that the line can still operate safely under fire temperature of more than 1000 ℃.

Because all the materials used are inorganic materials, and the structure is dense and hard, the product has the electrical, mechanical and environmental withstand properties that can not be compared with the conventional VV, YJV, yjy and other (organic cables).

It has high temperature resistance, fire prevention, explosion-proof and non combustion. It can run continuously for a long time at 250 ℃ and can also maintain 180min short-time operation under the limit state of 1000 ℃.

For BTT series Mi cables, the domestic implementation standard is gb/t 13033-2007 mineral insulated cables and terminals with rated voltage of 750V and below, and has not been updated so far. It can be seen from the release time of the specification that the stable state of product standards can be said to be the most mature Mi cable in technology.

BTT series rigid cables have good technical performance advantages, but also have problems such as difficult construction, short manufacturing length and complex intermediate joint processing technology. In order to solve the above problems, a variety of flexible cables have been developed in China.

This also brings us a lot of difficulties in the selection of engineering design.

3. Flexible cable named (bbtrz)

When the mineral insulated cable was introduced to China in the early stage, the copper sheath was often cracked because of the immature technology. Therefore, magnesium hydroxide was used as the sheath instead of copper sheath.

So (T) is changed to (b), and B is mineral.

The product structure consists of copper strand, mica tape insulation, irradiation crosslinked polyethylene water barrier, magnesium hydroxide fire protection sheath and low smoke halogen-free sheath.

Bbtrz, as a series of flexible mineral insulated cable models, has been highly recognized by many design institutes, owners and users, and has been widely used in various large-scale building fire lines in China.

Although the fire resistance tests of C, W and Z of the circuit integrity of bs-6387 can be passed, the mineral insulated cable does not use metal sheath such as () copper).

With the development of national comprehensive level, the structure of non combustible cable of mineral insulation is officially defined as “composed of copper core, mineral insulation material, copper and other metal sheath” in the code for fire protection design of buildings (GB 50016-2014) promulgated and implemented in 2015.

Because the series does not contain metal sheath, it has gradually withdrawn from the stage of fire protection application, and is no longer classified as “mineral insulation non combustible cable”.

4. Flexible cable named after [bttrz, yttw, rttz]

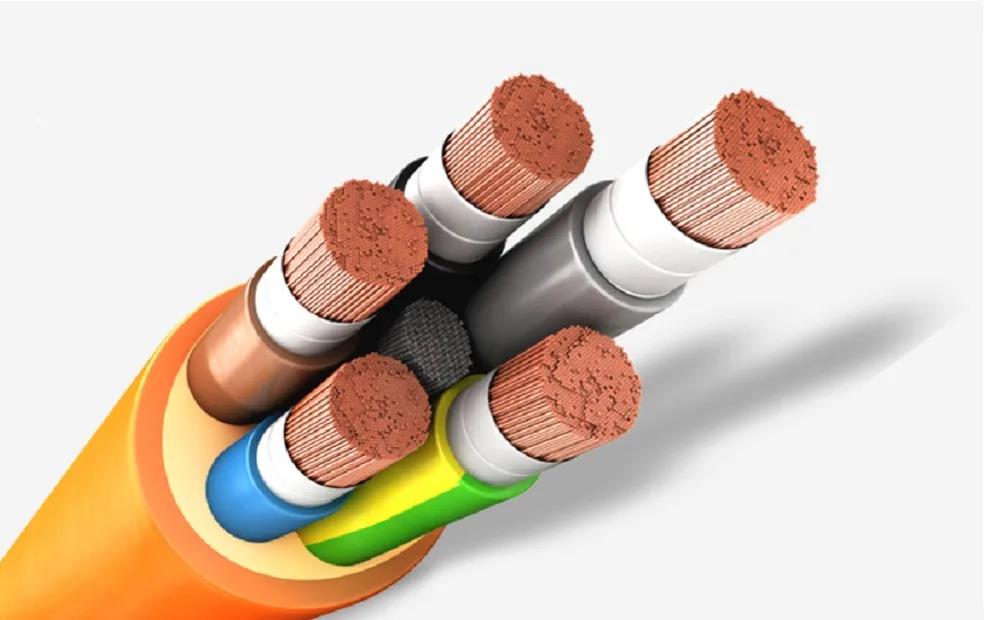

In fact, the three named Mi flexible cables have the same structure, all of which are called flexible rolled copper sheathed mica tape mineral insulated cables.

The product structure consists of copper pipe sheath composed of multi strand copper strand, mica tape mineral insulation wrapping, alkali free glass fiber dense filling and copper strip longitudinal welding.

picture

Before the relevant domestic standards were not issued, the bttrz flexible cable, which was developed and named by the manufacturer, was mainly different from bttz rigid cable, which highlighted (soft), so it was added (R) on the basis of bttz naming.

Later, the domestic construction industry standard: jg/t 313 was promulgated and implemented in 2011, and bttrz named by the manufacturer was changed to yttw. However, this naming rule is not in line with the domestic cable naming method, and many people can not accept it.

Later, the national standard was promulgated and implemented by the National Standardization Commission in 2017: gb/t 34926, which named the former flexible cable rttz.

So bttrz = yttw = rttz. In addition, before the relevant standards were issued, the flexible cables were named by different manufacturers: bttw, Btte and btwtz, which can be described as various.

It is obvious that the flexible cables meet the requirements of gb50016-2014, and the fire resistance type test meets the most stringent requirements of C, W and Z of bs-6387.

5. Flexible cable named (ng-a, btly)

Ng-a and btly series cables belong to the same category. They use aluminum as the main material metal pipe extrusion instead of copper tube pull sheath, which not only simplifies the production process and improves the efficiency, but also reduces the product cost (aluminum is only 1/10 of the comprehensive cost of copper).

The product structure consists of copper strand, mica tape insulation, seamless aluminum tube sheath, oxygen insulation layer filling, isolation refractory layer and low smoke and halogen-free sheath.

picture

The reason why aluminum tube can replace copper pipe is not melted under high temperature flame, which is due to the expanded refractory layer extruded by the outer part of the aluminum pipe.

It is foamed and solidified under the fire, forming a thick barrier to block the direct effect of flame on aluminum pipe. The insulation stability of mica tape can be improved (the insulation resistance will decrease with the increase of temperature).

According to the structure form and type test, it also meets the requirements of grade C, W and Z of gb50016-2014 and bs-6387. The insulation performance of mica tape inside the insulation layer (Mg (OH) 2 or Al (OH) 2 mineral material) on the outer layer of aluminum sheath has been improved.

However, ng-a (btly) series cables are not flexible cables specified in jg/t 313 and gb/t 34926 standards, and only enterprise standards are supported at present.

6. Summary

The above Mi cables are simply combed as follows:

(1) Rigid cable: BTT, structure form and product performance are in accordance with international and domestic specifications.

(2) Flexible cable: RTT and yttw, the fire resistance performance of the product meets the most stringent level tests of C, W and Z of bs6387, and the structure form meets the national specifications.

(3) Flexible cable: ng-a and btly, the fire resistance performance of the product meets the most stringent level tests of C, W and Z of bs6387, and the structure form meets the national standards, but only [enterprise standard] is supported.

From the above situation, the performance of flexible cable meets the requirements of the specification, and the length of a single cable is long and the construction is relatively easy. We will surely think, “can flexible cable replace rigid cable?”