Extrusion process is an indispensable part in cable manufactor, which includes insulation and sheath production process. Insulation production methods include coating, winding, extruding and their combination. Now the main insulation production is coating (winding wire, no longer in the scope of production license management) and extrusion (wire and cable).

1、 Plastic extrusion equipment and mould

1. Plastic extrusion equipment: extruder

1.1 working principle of the extruder: the screw of specific shape is used to rotate in the heated barrel, and the plastic sent from the hopper is pressed forward to make the plastic plasticize evenly. The plastic is extruded into products of various shapes through the head and molds of different shapes.

1.2 basic structure of extruder: the extruder is composed of extrusion system, transmission system and heating system (cooling).

1.2.1 extrusion system (including screw, barrel, hopper, head and die)

① Screw: screw is an important part of the extruder. It is made of high strength, heat-resistant and corrosion-resistant alloy steel. Its function is to push the plastic forward, produce pressure, stir, and produce friction heat with the plastic when rotating, so as to melt the plastic and continuously send the melt into the extruder. It is directly related to the application scope and productivity of the extruder.

② The barrel is a metal barrel, which is generally made of alloy steel or composite steel lined with alloy steel with high strength of heat resistance and pressure resistance, strong wear resistance and corrosion resistance. It and screw constitute the basic structure of the extrusion system for plastic plasticization and conveying. The length of the barrel is generally 15 ~ 30 times of its straight diameter, so as to make the material fully heated and plasticized. The barrel should have enough thickness, rigidity and smooth inner wall. A resistance or induction heater measuring device and a cooling system are installed outside the barrel.

③ The hopper is usually a conical container with a capacity of at least 1 hour. The bottom of the hopper is equipped with a device for cutting off the material flow. The side of the hopper is equipped with a sight hole for calibration and measurement.

④ The head is the forming part of the extruder. The head is mainly composed of filter device (perforated plate and screen), connecting pipe, diverter, mold core seat, mold, etc.

1.2.2 transmission system

Its function is to ensure that the screw rotates at a constant speed with the required torque and speed. Generally, Weidong system includes three necessary links: the prime mover, the transmission and the reducer. It is required that the rotation speed of screw should be stable and not change with its load, so as to ensure the uniform quality of products. But in different occasions, the screw is required to be able to change speed to meet the requirements of extruding products of different specifications with one equipment. For this reason, drive motor generally uses rectifier motor, DC motor, etc.

1.2.3 heating and cooling system

Function: through the heating or cooling of the barrel, to ensure that the plastic is always extruded within its process temperature range.

① Heating method of the extruder: when the screw speed of the extruder is kept constant, the main factor affecting the stability of the rubber output is the body temperature of the extruder.

There are usually two heating methods for cross-linking extruder, which are carrier heating (such as adding hot water) and resistor heating. The carrier heating is characterized by uniform heating and not easy to produce local overheating, but the carrier heating temperature has high requirements on the sealing performance of the system and high cost. Therefore, it can be used in the extruder with higher temperature control requirements.

② Cooling of plastic machine: in the extrusion process, the temperature of the plastic in the barrel is often too high and the heat is too much. If too much heat is not discharged in time, it is easy to cause “pre crosslinking” of the material; The extruder is generally cooled in two parts: barrel cooling and head cooling.

a. Barrel cooling (there are two methods of barrel cooling, air cooling and water cooling)

From the cooling effect, the air cooling is relatively soft, the cooling speed is slow, and the water cooling speed is fast, but it is relatively fierce, and it is easy to cause strong “thermal vibration”. The design of the water cooling system is relatively complex. In addition to its good cooling effect, it should also have good sealing to prevent leakage, so that when cooling is not needed, the water cooling system can be used for cooling, It is better to make all the water in the cooling system escape, so as to avoid the blockage of the cooling system due to the scale generated by the water storage. The structure should also be conducive to maintenance. Most of the current water cooling systems turn out the spiral groove on the outer surface of the barrel, and then coil the cooling pipe.

b. Screw cooling

The main purpose of the cooling screw is to prevent the plastic from overheating. In addition, the feeding section of the cooling screw is also conducive to the conveying of materials to the machine head. The cooling medium into the screw is usually water, and the water temperature can maintain a certain value according to the requirements. Even the cooling length of the screw can be adjusted, sometimes the whole length of the screw can be cooled, sometimes only part of the screw can be cooled, and the screw temperature of the latest designed extruder can be adjusted by zones.

1.2.4 screw parameters of extruder

The main parameters of screw are diameter length diameter ratio, compression ratio, pitch, groove width, helix angle, clearance between screw and barrel, etc.

① Screw diameter D: the size of the extruder is usually expressed by the screw diameter. The larger the diameter is, the larger the amount of glue will be. The extrusion amount is approximately proportional to its square. Therefore, a small increase in the screw diameter will cause a significant increase in the extrusion amount.

② Length diameter ratio L / D: the ratio of length L and diameter D of screw working part. When the screw diameter is fixed, increasing the length to diameter ratio means increasing the length of the screw. The larger the length to diameter ratio is, it is conducive to the full plasticization of the material. At the same time, it can produce greater pressure to ensure that the product is more dense and improve the quality. However, too large ratio of length to diameter is not enough, resulting in over plasticization of cross-linked materials, leading to early cross-linking of materials. For extruders of cross-linking units, the ratio of length to diameter is generally between 20 and 25 times.

③ The compression ratio is the ratio of the volume of the first slot in the feeding section to the volume of the last screw slot in the homogenizing section. The selection of compression ratio should not be determined according to the raw materials. The properties of plastics are different, and the compression ratio is also different. The particles are large and the compression ratio is small; The compression ratio of LDPE is 2 ~ 3 times.

④ Groove depth h: the difference between the outer radius and the root radius of the thread. According to the compression requirements, the groove depth of the feeding section is greater than that of the melting section, and the melting section is greater than that of the homogenizing section. The large groove depth of the feeding section is conducive to improving its conveying capacity. The grooves of the melting section and homogenizing section are shallow, and the screw can produce a higher shear speed for the material, It is beneficial to the heat transfer from the cylinder wall to the material and the mixing and plasticizing of the material.

2. Die of extruder

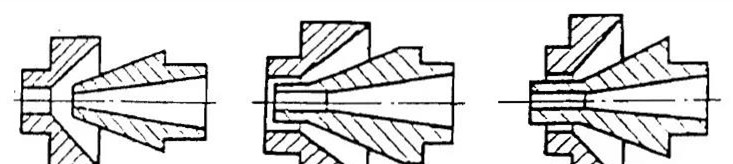

2.1 the die of extruder is divided into extrusion type, semi extrusion type and extrusion type( (see figure below)

2.2 characteristics of various molds:

2.2.1. Advantages of extrusion type

1) The structure of extruded plastic layer is compact and firm.

2) The insulation is closely connected with the conductor without gap, and the insulation strength of the extruded layer is reliable.

3) The outer surface is flat and smooth.

2.2.2. Disadvantages of extrusion type

1) It is not easy to adjust the eccentric core.

2) The accuracy of die matching is high, and the product quality is highly dependent on the die.

3) The bending of extrusion line is not good.

2.2.3 advantages of tube extrusion

1) The extrusion speed is fast.

2) The operation is simple and the core adjustment is easy.

3) Large clearance, small wear and long service life.

4) It is convenient to match the mold.

5) The extrusion strength of plastics increases with the directional drawing of plastics.

6) The sheath thickness is easy to control.

2.2.4 disadvantages of tube extrusion type

1) The density is poor.

2) The combination of plastic and wire core is poor.

2.2.5 semi extruded pipe: it absorbs the advantages of extruded pipe and extruded pipe.

2、 Crosslinking methods of cross-linked polyethylene materials are divided into chemical and physical methods

1. Chemical crosslinking: peroxide crosslinking (1) steam crosslinking (SCP); 2. Infrared crosslinking (RCP) and dry crosslinking; 3. Mdcv crosslinking; 4. Pressurized lava salt crosslinking (PLCV) process; 5. Silicone oil crosslinking (fzcv) process.) And silane graft crosslinking (one-step, two-step, copolymerization).

2. Physical crosslinking: high energy radiation crosslinking.