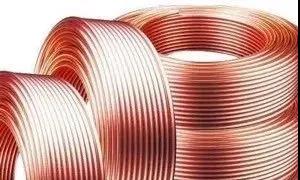

Pure copper is a purplish red metal, commonly known as “red copper”, “red copper” or “red copper”. Pure copper is ductile. Pure copper, the size of a drop of ACSR Cable, can be drawn into two kilometers of filaments or rolled into almost transparent foil larger than a bed. The most valuable property of pure copper is its excellent conductivity, second only to silver in all metals, so it has become the “leading role” of the electrical industry.

Pure copper is more widely used than pure iron. Every year, 50% of copper is electrolyzed and purified into pure copper for electrical industry. The pure copper mentioned here is really very pure, with a copper content of more than 99.95%. A very small amount of impurities, especially phosphorus, arsenic, aluminum, will greatly reduce the conductivity of copper. The oxygen content in copper (easily mixed with a small amount of oxygen in copper smelting) has a great influence on the conductivity, so the copper used in electrical industry must be oxygen free copper. In addition, lead, antimony, bismuth and other impurities will make copper crystal can not be combined, resulting in hot brittleness, also affect the processing of pure copper.

This kind of pure copper with high purity is usually refined by electrolysis: the Impure Copper (crude copper) is used as anode, the pure copper as cathode, and the copper sulfate solution as electrolyte. When the current passes through, the Impure Copper on the anode gradually melts, and the pure copper gradually precipitates on the cathode. Copper thus refined; The purity can reach 99.99%.

Red copper is a relatively pure copper, generally can be considered as pure copper, conductivity, plasticity are better, but the strength, hardness is poor.

Properties and uses of brass

Brass is a kind of copper containing other alloy components. Its price is cheaper than that of red copper. Its conductivity and plasticity are worse than that of red copper, but its strength and hardness are higher.

Brass is an alloy of copper and zinc. The simplest brass is copper zinc binary alloy, which is called simple brass or ordinary brass. The higher the content of zinc in brass, the higher the strength and the lower the plasticity. The zinc content of brass used in industry is not more than 45%. No matter how high the zinc content is, brittleness will occur and the alloy properties will deteriorate.

Adding 1% tin to brass can significantly improve the corrosion resistance of brass in seawater and marine atmosphere, so it is called “Navy brass”. Tin can improve the machinability of brass. Lead yellow copper is what we usually call easy to cut national standard copper. The main purpose of adding lead is to improve the machinability and wear resistance, but lead has little effect on the strength of brass. Carved copper is also a kind of lead brass. Most brasses have good color, processability and ductility, and are easy to be electroplated or coated.

In industry and civil use, different materials are selected according to different use characteristics. If make electric wire, requirement is softer, red copper is better. If the connection piece is made, brass is often used for the screw.

Properties and uses of bronze

It originally refers to copper tin alloy. Later, except brass and Cupronickel, all copper alloys are called bronze, and are often preceded by the name of the first major additive element. Tin bronze has good castability, antifriction and mechanical properties, and is suitable for manufacturing bearings, worm gears and gears. Lead bronze is widely used in modern engines and grinding machines. Aluminum bronze has high strength, good wear resistance and corrosion resistance. It is used for casting high load gears, shaft sleeves, marine propellers, etc. Beryllium bronze and phosphor bronze have high elastic limit and good conductivity. They are suitable for manufacturing precision springs and electrical contact elements. Beryllium bronze is also used to manufacture non sparking tools used in coal mines and oil depots.

Properties and uses of white copper

Copper alloy with nickel as the main additive. Copper nickel binary alloy is called ordinary white copper; Copper alloy with manganese, iron, zinc, aluminum and other elements is called complex copper. Industrial white copper can be divided into structural white copper and electrical white copper. The structural white copper is characterized by good mechanical properties, corrosion resistance and beautiful color. This kind of white copper is widely used in manufacturing precision machinery, chemical machinery and ship components. Electrical white copper generally has good thermoelectric properties. Manganin, constantan and Kaotong are white manganin copper with different manganese contents. They are used to manufacture precision electrical instruments, varistors, precision resistors, strain gauges and thermocouples.

How to distinguish red copper, brass, bronze and white copper

White copper, brass, red copper (also known as “red copper”) and bronze (cyan gray or grayish yellow) are distinguished from each other in color, among which white copper and brass are very easy to distinguish; It is difficult to distinguish red copper from pure copper (impurity < 1%) and bronze (about 5% of other alloy components). Before oxidation, the color of red copper is brighter than that of bronze, and the bronze is slightly cyan or yellow and dark; After oxidation, red copper turns black, while bronze turns Turquoise or chocolate.