In 1988, a transoceanic submarine optical cable (TAT-8) system was installed between the United States, Britain and France, with a total length of 6,700 kilometers.This optical cable contains 3 pairs of optical fibers, each pair has a transmission rate of 280Mb/s, and the relay station distance is 67 kilometers. This is the first communication submarine cable across the Atlantic Ocean, marking the arrival of the era of submarine cable. In 1989, the submarine optical cable (13,200 kilometers in length) across the Pacific was also successfully constructed. Since then, submarine optical cables have replaced concentric cables in the field of intercontinental submarine cables across the ocean, and submarine cables have no longer been laid between oceans.

Optical fiber has large transmission capacity and long distance between relay stations, which is suitable for long-distance communication under the sea. Optical fibers used in submarine optical cables have higher requirements than optical fibers used in terrestrial optical cables; they require low loss, high strength, long manufacturing length, and long relay distances of optical cables, generally above 50 kilometers.

The transmission performance of optical fibers is required Will not change within 25 years. In terms of the structure of the submarine optical cable: it is required to withstand strong pressure and tension, especially for deep-sea optical cables (optical cables laid on the seabed at a depth of more than 1,000 meters). In addition to the weight of the optical cable itself, sea waves must be added to the laying and maintenance operations. The dynamic stress added to the optical cable, under such a large load condition, the strain of the optical cable must be limited to 0.7-0.8%; the structure of the submarine optical cable requires strong and light materials, but light metal aluminum cannot be used because aluminum and sea water will Hydrogen is generated in response to electrochemistry, and hydrogen molecules diffuse into the glass material of the optical fiber, which increases the loss of the optical fiber. Therefore, the submarine optical cable must not only prevent hydrogen from being generated inside, but also prevent hydrogen from penetrating into the optical cable from the outside. For this reason, in the early 1990s, a carbon- or titanium-coated optical fiber was developed to prevent hydrogen penetration and chemical corrosion. The optical fiber connector is also required to be high-strength, requiring the connection to maintain the strength of the original optical fiber and the surface of the original optical fiber from damage.

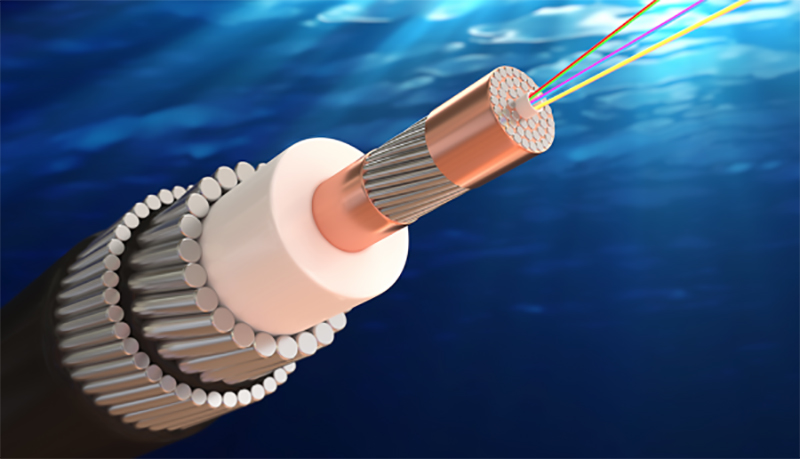

According to the above requirements and characteristics, the basic structure of the submarine optical cable is to spirally wrap the optical fiber after one or two coating treatments around the center and around the reinforcing member (made of steel wire). The structure of several typical deep-sea optical cables: deep-sea optical cables, the optical fiber is arranged in a spiral U-shaped grooved plastic skeleton, and the groove is filled with grease or elastic plastic to form the core. The core is wrapped with high-strength steel stay wire. During the wrapping process, all the gaps should be filled with waterproof material. Then a layer of copper tape is wrapped around the steel wire and the seam is welded to make the steel wire and the copper tube form a resistance A combination of compression and tension, this copper tube is also a conductor that carries a remote current. A layer of polyethylene sheath should be added on the outside of the steel wire and copper pipe. Such a tight multi-core cable structure is to protect the optical fiber, prevent breakage and prevent the intrusion of seawater, and also to withstand huge tension and pressure during laying, recovery and repair.

Even with such tight protection, in the late 1980s, there were instances where the polyethylene insulators of deep-sea optical cables were bitten by sharks causing power failures. The remote power supply of the submarine cable system is very important, and the repeaters along the submarine cable rely on the remote power supply of the landing station. The digital repeater used in the submarine optical cable has many functions, and the power consumption is several times larger than that of the analog repeater of the submarine cable. The power supply requires high reliability and cannot be interrupted. Therefore, in areas where sharks are infested, two layers of steel tape and a layer of polyethylene outer sheath should be added to the outside of the submarine optical cable.

In the 1990s, submarine optical cables and satellite communications have become the main means of contemporary intercontinental communications. From 1989 to the end of 1998, my country has successively participated in the construction and investment of 18 international submarine optical cables. The first international submarine cable system to land in China was the China-Japan (C-J) submarine cable system built in December 1993. In February 1996, the China-Korea submarine optical cable was completed and opened, and landed in Qingdao, China and Taian, South Korea, with a total length of 549 kilometers; in November 1997, China’s participation in the construction of the ball submarine optical cable system (FLAG) was completed and put into operation. The intercontinental optical cable systems landed in China were landed in 12 countries and regions including the United Kingdom, Egypt, India, Thailand, and Japan. The total length is more than 27,000 kilometers, of which the Chinese section is 622 kilometers. The Asia-Europe submarine optical cable system jointly initiated by the company is under construction. The system connects Asia, Europe and Oceania. The system has landed in 33 countries and regions. The total length is 38,000 kilometers. It is the longest submarine optical cable in the world. 8-wavelength wavelength division multiplexing technology, the design capacity of the backbone route is as high as 40Gb/s, landed in China’s Shanghai and Shantou, completed and opened at the end of 1999.

The volume of intercontinental communications undertaken by submarine optical cables has increased year by year, and has exceeded that of satellite communications, becoming the main force of modern intercontinental communications.