The design of submarine optical cable: anti-corrosion, anti-seepage, but also against sharks, compared with coaxial cable, optical fiber is quite obvious advantages, but its own is quite fragile, so this protection of optical fiber submarine cable peripheral protection structure put forward higher requirements. Specifically, the design of submarine optical cable must ensure that the internal optical fiber is not affected by external forces and the environment. Its basic requirements include adaptability to submarine pressure, abrasion resistance and non-corrosion, etc. It also has to prevent hydrogen from forming inside (and therefore not using aluminum) and hydrogen from outside (preventing gas infiltration). In addition, it must be properly armored to protect it from trawlers, anchors and sharks. When the cable is broken, but also as much as possible to reduce the length of seawater into the cable; At the same time, it can withstand the tension during laying and recovery; Last but not least, the service life of submarine cables is generally required to be over 25 years.

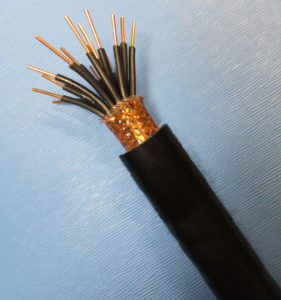

Based on the above requirements, the current design structure of submarine cables usually consists of one or two coating treatments of the fiber in a spiral wrapping around the center, and then reinforcing members (made of steel wire) wrapped around (usually 69 mm in diameter). Specifically, it includes: polyethylene layer, polyester resin or asphalt layer, steel strand layer, aluminum waterproof layer, polycarbonate layer, copper or aluminum tube, paraffin layer, alkane layer, fiber bundle, etc.

Laying process: from relying on the tide to relying on robots

The laying project of submarine optical cable is recognized as one of the most complicated and difficult large-scale projects in the world, which is not difficult to understand why the service life of submarine optical cable is required to reach more than 25 years, because laying once is very troublesome! The laying process of submarine optical cable can be divided into two parts, namely, the laying of shallow sea area and the laying of deep sea area. In the deep sea area, the laying of submarine optical cable has to go through three stages, namely, exploration and cleaning, sea cable laying and burial protection. The laying of submarine cables mainly depends on the cable laying ships and underwater robots. The cable laying ships should pay special attention to the sailing speed and cable release speed, so as to control the water inlet Angle and laying tension of the cable, so as to avoid damaging the fragile optical fibers in the cable due to too small bending radius or too large tension.

As shown in the figure above, this is the laying process of an undersea optical cable. In shallow sea areas, the laying ship stays a few kilometers away from the coast, and the cable placed on the floating bag is pulled to the shore by the shore tractor. Then the floating bag is removed to make the cable sink to the sea floor. In the deep sea, the laying ship is mainly responsible for releasing optical cables, and then the underwater detector is combined with the underwater remote control vehicle for underwater monitoring and adjustment, so as to avoid uneven and rocky areas on the seabed. The robot then proceeded to a three-step operation: first, it created a trench about 2m deep in the sea floor, using high-pressure flushing; The second step is to put the cable into the trench; Third, cover it with the sand nearby.

Special to note here is that a intercontinental submarine cable is difficult to a complete laid, because at present the most advanced optical cable laying ship can only carry 2000 kilometers of fiber optic cable (and now laying rate can only reach 200 km/day), thus laid to segments, and each paragraph “cable docking”, needs to be done in laying the ship, and requires high technology.