In the production process of rubber sheathed AAC Cable, there are often appearance defects, such as unsmooth surface; Clinker particles (early vulcanized rubber particles) or impurities on the surface; Scratch and scratch on the surface of wires and cables; Surface collapse; There are hemp patterns on the surface.

The following are five common causes of appearance defects of rubber sheathed ACSR Cables:

1. The die sleeve bearing line is too long or too short, the die opening is not smooth and the hole diameter is too large; Low head, die or body temperature; Low plasticity of rubber may lead to unsmooth surface of rubber sheathed cable.

2. The supplied rubber is not clean and contains impurities; The scorch time of rubber is too short; The temperature of rubber extrusion body, head or die is too high; The rubber flow in the head is not smooth, and there is a dead corner of rubber retention; Unsmooth screw and viscose may lead to clinker particles (early vulcanized rubber particles) or impurities on the surface of rubber sheathed cable.

3. The die sleeve is not smooth and has no chamfer; Impurities or clinker particles block the die mouth; Abrasion of dragging pipe in vulcanization pipe; The small aperture of the sealing rubber gasket at the outlet of the vulcanization pipe may cause scratches and scratches on the surface of the rubber sheathed cable.

4. The hole diameter of die sleeve is too large; The gap between the outer strands and monofilaments of the conductive core is too large, and the outer diameter of the cable core is uneven; The rubber has small plasticity and poor viscosity; Impurities in rubber; Small mold distance and pressure may cause the surface collapse of rubber sheathed cable.

5. The hole diameter of die sleeve is too small; Insufficient rubber extrusion and insufficient filling of wire core gap; Conductive core or cable core jumper; Short distance between molds may lead to twist on the surface of rubber sheathed cable.

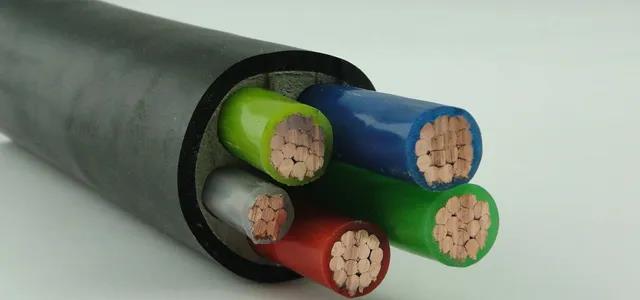

Rubber sheathed cable is a kind of soft and movable cable with multi strand fine copper wire as conductor and wrapped with rubber insulation and rubber sheath. Generally speaking, it includes general rubber sheathed flexible cable, electric welding machine cable, submersible motor cable, radio device cable and photographic light source cable.

Rubber sheathed cables are widely used in various electrical equipment, such as mobile power lines for daily appliances, electric machinery, electrical devices and appliances. At the same time, it can be used under indoor or outdoor environmental conditions. According to the external mechanical force on the cable, the product structure is divided into light, medium and heavy. There is also appropriate connection on the section.

General light rubber sheathed cables are used in daily electrical appliances and small electric equipment, which are required to be soft, lightweight and good bending performance;

Medium sized rubber sheathed cables are widely used in agricultural electrification except for industrial use;

Heavy duty cables are used in such occasions as port machinery, searchlights, large hydraulic drainage and irrigation stations in domestic industry, etc. This kind of products have good universality, complete series specifications, good and stable performance.

Waterproof rubber sheathed cable and submersible pump cable: mainly used for supporting submersible motor, with models of JHS and JHSB.

Cables for radio devices: now we mainly produce two kinds of rubber sheathed ABC Cables (one shielded and one unshielded), which can basically meet the requirements. The models are wyhd and wyhdp.

Photographic cable products: with the development of new light sources, they have small structure and good performance, meet the needs of indoor and field work, and gradually replace some old products with heavy weight and poor heat resistance.

Operation method:

1. Set the temperature and time according to the vulcanization system of the compound

2. Wipe and wash the repair place with rubber and ink diluent, especially the joint shall be fully treated.

3. Cut the repair rubber properly according to the size of the gap, and pay attention not to be too much or too little,

4. Plug the cut rubber in the gap, and pay attention that the rubber shall not be higher than the circumference of the wire.

5. Wrap it with high temperature resistant PP tape. And put it into the tubular die cavity slightly smaller than the wire diameter, lock the upper and lower dies, and make the supplemented position have a certain pressure. Note that the die cavity diameter is slightly smaller than the wire diameter by 0.1 ~ 0.2mm.

6. When the vulcanization time is up, take out the product. If a small amount of rubber overflows, repair it with a sharp blade and wipe it with diluent.