The choice of cable insulation type should meet the following requirements:

1 Under the operating voltage, operating current and its characteristics and environmental conditions, the cable insulation characteristics should not be less than the conventional expected service life.

2 The selection should be based on factors such as operational reliability, ease of construction and maintenance, and comprehensive economy of allowable maximum operating temperature and cost.

3 It shall meet the requirements of fire prevention places and shall be conducive to safety.

4 When it is clear that it is necessary to coordinate with environmental protection, an environmentally-friendly cable insulation type should be selected.

The selection of the insulation type of commonly used cables should meet the following requirements:

1 In addition to the selection of insulation type for medium and low-voltage cables, it shall comply with the provisions of Article 3.4.3~3.4.7 of this code.

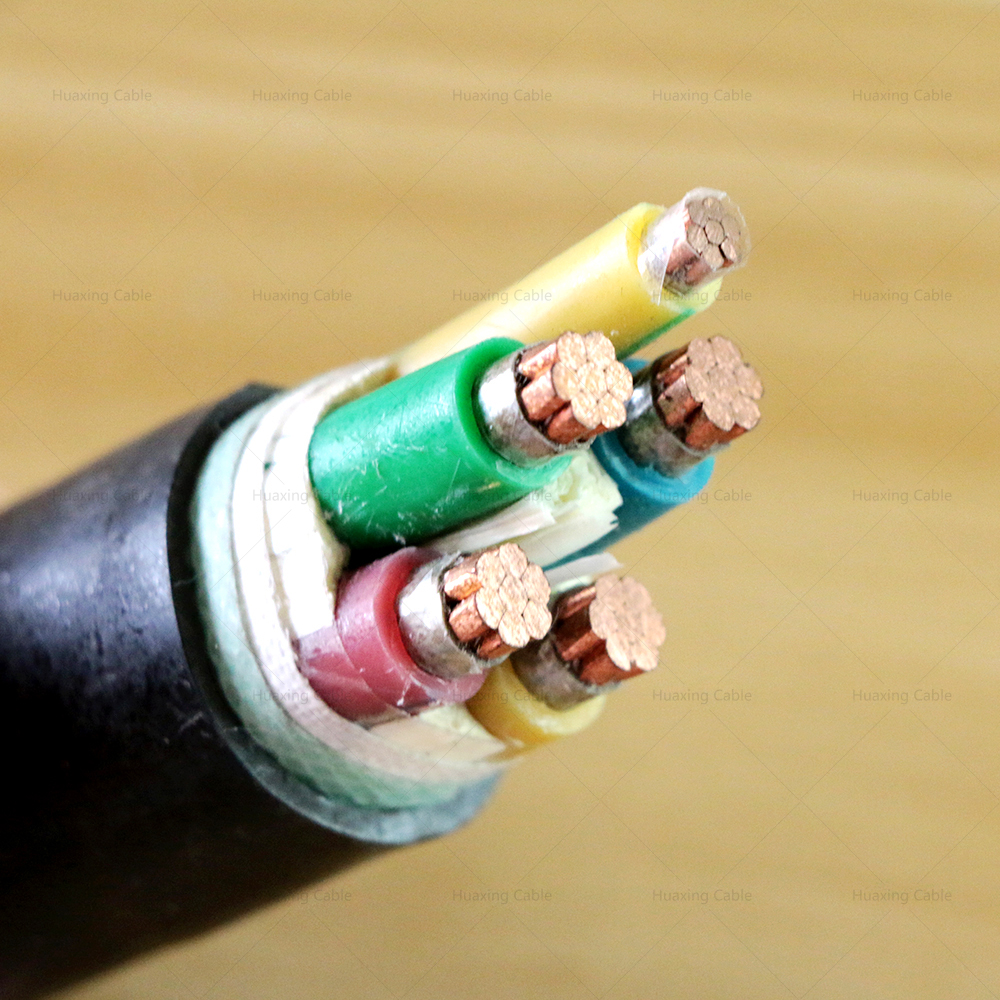

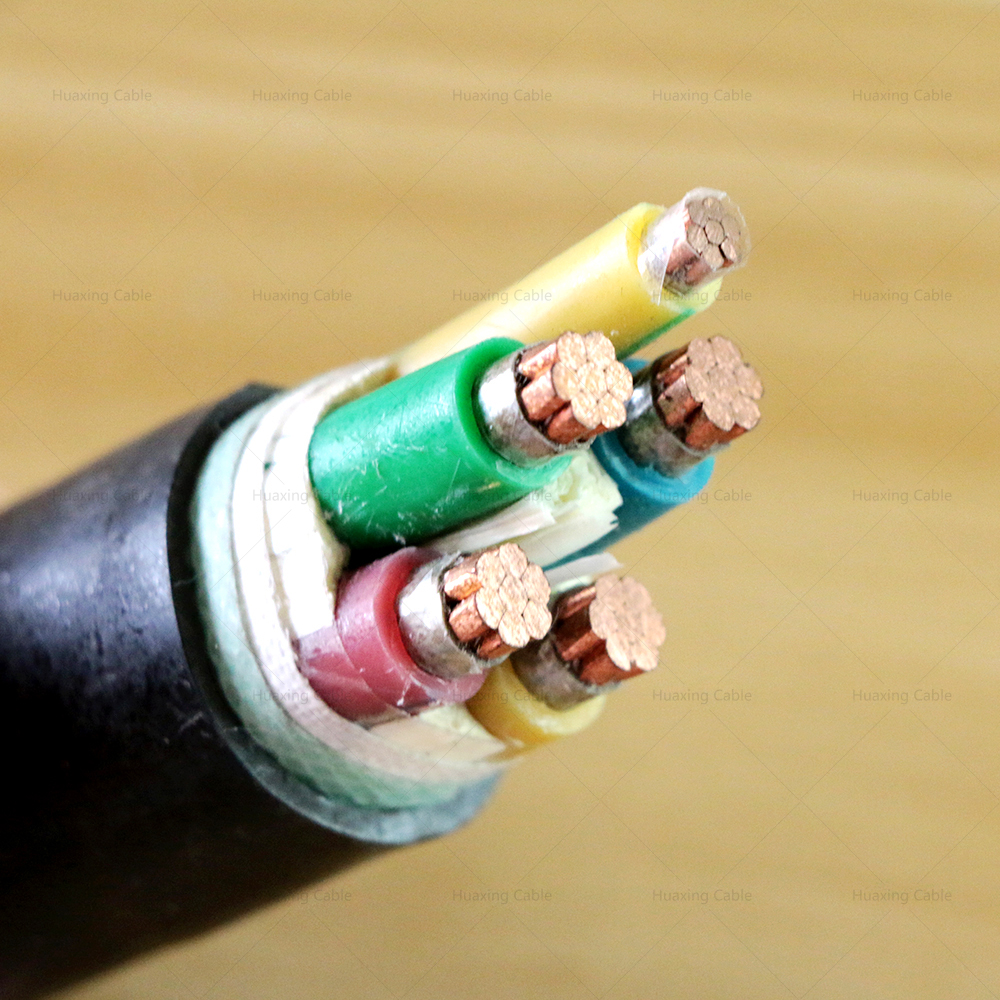

Linked polyethylene type extruded insulation type, medium voltage cable should use cross-linked polyethylene (xlpe) insulation type.such as 600V XLPE ACWU90 AC90 cable.

When it is clearly necessary to coordinate with environmental protection, PVC insulated cables shall not be used.

2 The cable line in the high-voltage AC system should be of XLPE insulation type. In areas with more operating experience, self-contained oil-filled can be used

cable.

3 For high voltage DC transmission cables, non-drip impregnated paper insulation and self-contained oil-filled types can be selected. When it is necessary to increase the transmission capacity, half

The type of synthetic paper material construction.

Ordinary XLPE cables should not be used for DC transmission systems.

Cables such as rubber insulation should be used for circuits that are frequently bent and moved or require higher flexibility, such as mobile electrical equipment.

In the place where radiation is applied, cables with radiation resistance strength such as cross-linked polyethylene or ethylene-propylene rubber insulation should be selected according to the requirements of the insulation type.

Heat-resistant polyvinyl chloride, cross-linked polyethylene or ethylene-propylene rubber insulated cables should be selected for heat-resistant polyvinyl chloride, cross-linked polyethylene or ethylene-propylene rubber insulated cables according to the requirements of high temperature and duration and insulation type for high temperature above 60℃; minerals should be selected for high temperature above 100℃ Insulated cables.

Ordinary PVC insulated cables should not be used in high temperature locations.

For low temperature environments below 15°C, cross-linked polyethylene, polyethylene insulated, and cold-resistant rubber insulated cables should be selected according to the low temperature conditions and insulation type requirements.

PVC insulated cables are not suitable for low temperature environments.

In crowded public facilities and places with low-toxicity, flame-retardant and fire-proof requirements, cross-linked polyethylene or ethylene-propylene rubber and other non-halogen insulated cables can be used.

When fire protection has low toxicity requirements, PVC insulated cables should not be used.

Except for the cases specified in 3.4.5~3.4.7 of this code, PVC insulated cables can be used for circuits below 6kV.

For 6kV important circuits or cross-linked polyethylene cables above 6kV, the three-layer co-extrusion process characteristics of inner and outer semi-conductive and insulating layers should be used

The style.