The processing and production of bare conductor are carried out in accordance with the national standards. The latest domestic standard is: GB/T1179-2008. The relevant national standards used before are no longer used. Since the previous standards are relatively simple and clear, refer to It is very convenient to use. Except for the change in the representation method, the other conductor structure, performance and technical parameters have not changed. Therefore, many current power design, bidding and procurement units still use the 83 standard (ie: GB/1179-83).

1. bare conductor-a material used to transmit current, made of multiple insulated single wires twisted together.

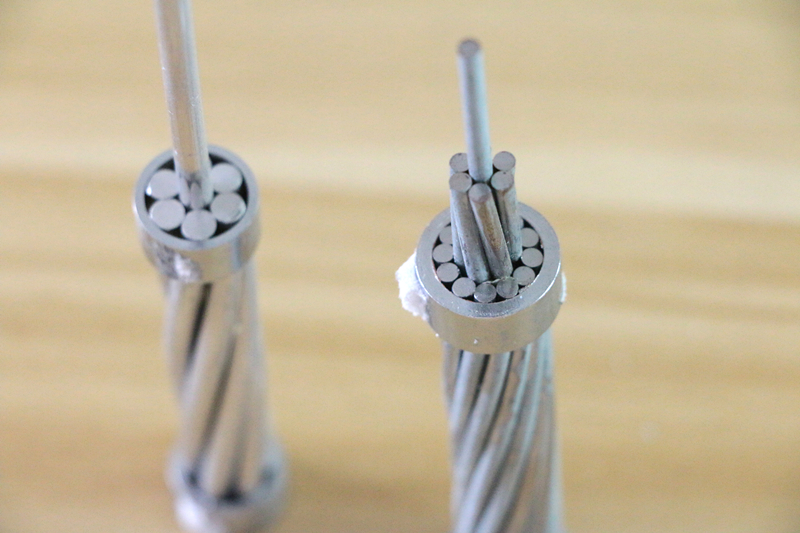

2. Concentric stranded wire —— a wire composed of one or more layers of single wires is spirally twisted around a central core, and the adjacent layers are twisted in opposite directions.

3. Twisting direction-the twisting direction of a layer of single wires, that is, the direction away from the observer. The right direction is clockwise, and the left direction is counterclockwise.

4. Pitch —— A single wire in the twisted wire forms the axial length of a complete spiral.

5. Pitch diameter ratio —— the ratio of the pitch of the single wire in the stranded wire to the outer diameter of the layer.

6. Steel ratio-the ratio of steel cross-sectional area to aluminum cross-sectional area expressed in percentage.

7. Cross-sectional area-the total cross-sectional area of all aluminum or aluminum alloy single wires that make up the wire.

8. Linear density——mass per unit length.

The General Type of bare conductors including AAC(All Aluminum Conductor), AAAC (All Aluminum Alloy Conducor),ACSR(Aluminum Conductor Steel Reinforced Cable),ACAR (Aluminum Conductor Aluminum Reinforced Cable) and etc .

The quality of the workmanship and stranding of the wire

1. Process quality requirements

a. The surface of the round aluminum wire should be smooth and clean

b. Any round aluminum wire in the 7-strand aluminum wire is not allowed to have a joint.

The aluminum stranded wire with more than 7 strands and the round aluminum wire in the steel core aluminum stranded wire are allowed to have joints, but the distance between the two joints on the finished stranded wire should not be less than 15 meters.

c. The joints should be smooth and round, usually cold-pressed butt welding joints.

d. Galvanized steel wire does not allow joints.

2. Stranding of wires

A. Single wire twisting should be even and tight;

b. All single wires should be twisted concentrically;

c. The twisting direction of the adjacent layers should be opposite, if not specified by the ordering party, the twisting direction of the outermost layer is “right”;

d. Each layer of single wires should be evenly and tightly twisted on the lower core or inner twisted layer;

E. For stranded wires with multiple layers, the pitch diameter ratio of any layer should not be greater than the pitch diameter ratio of the adjacent inner layer;

3. Technical requirements for finished wires

a. The finished wire should meet the technical conditions required by the bidding unit and meet the requirements of the GB/T 1179-2008 standard.

b. There should be no visible defects on the wire surface, such as obvious scratches, indentations, etc., and there should be no defects that are not commensurate with good products, and the surface should be smooth and clean without corrosion, blackening, and graying.

c. The pitch-to-diameter ratio of the wires is within the limits specified in GB/T 1179-2008. Once the stranding starts, the same stranding parameters are maintained for all the entire batch of wires shipped to a given destination. The steel core aluminum stranded wire provided is a product formed by one-time stranding.

d. The finished wire is a uniform cylindrical surface, and can withstand normal loading and unloading during transportation and installation without causing deformation that increases corona loss and radio interference.

e. The steel core aluminum stranded wire has no excessive drawing lubricants, metal particles and powders, and no defects that are inconsistent with the industrial products and the engineering process quality requirements of the bidding party. Factory products no longer require design measures to limit the occurrence of corona and radio interference.

F. The steel core of the wire is manufactured by a manufacturer.

g. When stranding, the steel core or partially stranded semi-finished products and strands to be stranded are stored in the factory for a long enough time to ensure that the steel core or partially stranded semi-finished products and the strands to be stranded The strands are at the same temperature and will maintain the same temperature throughout the stranding process.

h. Once the stranding and storage process has started, in order to make all the wires have the same stranding law as possible, follow the corresponding process for the insufficient part of the wire at the given destination.

I. The wire is suitable for tension stringing and also suitable for loose stringing. During normal winding, any lantern, loose strands, jumpers, broken strands and influences on the winding construction will be regarded as unqualified products.

J. The manufacturing of the wire and the twisting of the strands should ensure that there is no obvious twisting or loose strands after the wire is cut. The steel core is formed so that after the wire is cut and the aluminum single wire is peeled from the steel core according to the requirements of the joint, the steel core can be reassembled without difficulty, and it is easy to use one hand to sleeve the splice tube from the cut end of the wire into the steel core . Similarly, the molding of aluminum single wire also allows the aluminum wire to be easily reassembled, and it is convenient to use one hand to put the splice tube into the aluminum wire at the cut end of the wire, so that the twisting is tight and uniform, no strands are missing, and no jumps. Lines and continuous strands must not be biased.