1. What are the requirements for cable piping?

Answer: (1) The distance from the top of the pipe to the ground is 0.2m in the workshop, 0.5m under the sidewalk, and 0.7m in general areas;

(2) Pipe pits should be installed at the change direction and branch, and pits should also be added when the length exceeds 30mm;

(3) The pit depth is not less than 0.8m, and the manhole diameter is not less than 0.7mm;

(4) The drain pipe should have a drainage slope of 0.5% to 1% inclined to the pit.

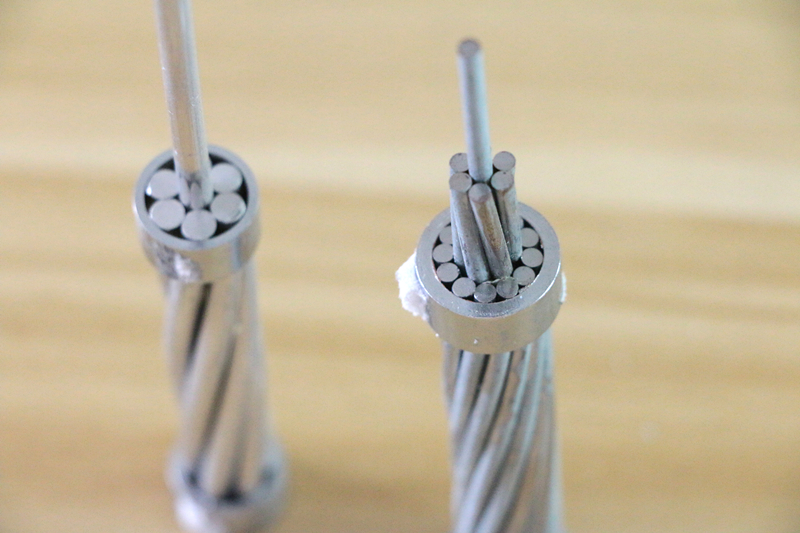

2. What are the requirements for the resistance of the cable conductor connection point?

Answer: The resistance of the connection point is required to be small and stable. The ratio of the resistance of the connection point to the conductor of the same length and the same cross-section should not be greater than 1 for the newly installed terminal head and intermediate head; This ratio should not be greater than 1.2.

3. What requirements should the design of cable joints and intermediate head meet?

Answer: The requirements that should be met are:

(1) High compressive strength and good conductor connection;

(2) High mechanical strength, low medium loss;

(3) Simple structure and strong sealing.

4. What is a cable fault? There are several common types?

Answer: Cable failure refers to the failure of the cable’s insulation breakdown during the preventive test or during the operation, which forces the aerial bundled cable 33-209 standard to power out due to insulation breakdown, wire burnout, etc. Common faults include ground faults, short-circuit faults, disconnection faults, flashover faults and mixed faults.

5. How to deal with the single-phase ground fault of the cable line?

Answer: Generally speaking, the damage to the cable conductor is only partial. If it is a mechanical damage and the soil near the fault point is relatively dry, local repairs can generally be carried out and a fake connector is added, namely Without sawing the cable core, only the fault point is insulated and sealed.

6. What tests and inspections should be carried out on power cables before laying?

Answer: Before laying, check whether the type, specification and length of the cable meet the requirements and whether there is external force damage. Low-voltage cables use a 1000V megohmmeter to remotely measure the insulation resistance, and the resistance is generally not less than 10MΩ, and high-voltage cables are measured with a 2500V megger. The resistance is generally not less than 400MΩ.

7. What should be paid attention to when laying cables in the main workshop?

Answer: When laying cables in the main factory building, generally pay attention to:

(1) All control cables leading to the centralized control room should be laid overhead;

(2) 6KV cables should be laid in tunnels or pipes, and the high groundwater level can also be laid overhead or pipes;

(3) For 380V cables, tunnels, trenches or pipes should be used when the two ends of the cable are at zero meters. When one end of the equipment is on the top and the other is on the bottom, it can be partially overhead laid. When the local water level is high, it should be overhead.

8. Where are the inner and outer shielding layers of power cables? What material is used? What’s the effect?

Answer: In order to make the insulation layer and the cable conductor have better contact and eliminate the increase in the electric field strength of the conductor surface caused by the unevenness of the conductor surface, the conductor surface is generally covered with an inner shielding layer of metalized paper or semiconductor paper tape. In order to make the insulating layer and the metal sheath have better contact, generally the outer surface of the insulating layer is covered with an outer shielding layer. The material of the outer screen layer is the same as that of the inner screen layer, and sometimes copper tape or braided copper ribbon is tied outside.

9. Briefly describe the composition and performance of epoxy resin compound.

Answer: The epoxy resin compound is composed of epoxy resin added with hardener, filler, toughening agent and diluent. Has the following properties:

(1) Have sufficient mechanical strength;

(2) Excellent electrical performance;

(3) Stable electrical performance;

(4) It has sufficient adhesion to non-ferrous metals;

(5) Good corrosion resistance;

(6) When used outdoors, it is resistant to rain, light, and humidity.