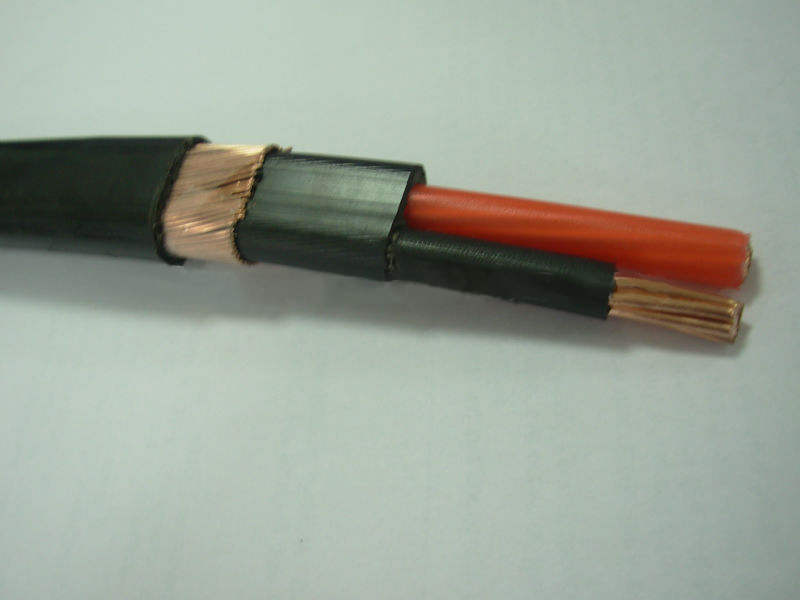

1. Copper and aluminum have different potentials. The part in contact with copper and aluminum will accelerate the oxidation of the aluminum wire due to the galvanic cell reaction. To join together, a copper – aluminum transition wire clip or transition wire pipe must be used.

2. This is a question of chemistry, the chemical properties of metals are relatively lively and not lively, such as gold, never rust, which means gold chemical inertness, easy to rust iron, iron is lively than gold, if two metal together will accelerate active metal oxide, aluminum and copper, aluminium is lively, two kinds of cable connection, will accelerate aluminum oxidation (rust), affect the use.

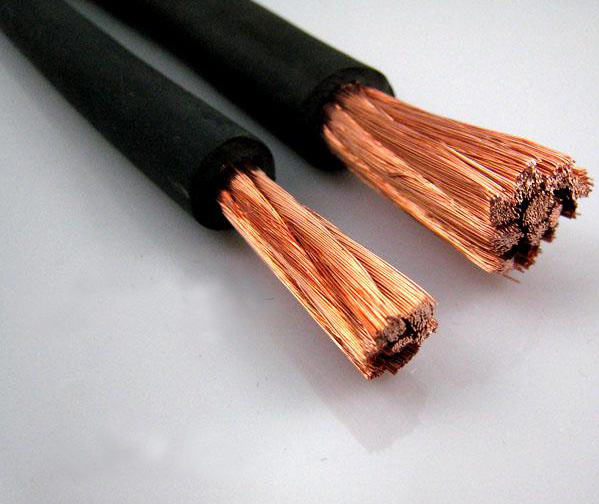

3. When copper and aluminum conductor are directly connected, the contact surface of the two metals is easy to form electrolyte under the action of moisture in the air, carbon dioxide and other impurities, thus forming a galvanic cell with aluminum as the negative pole and copper as the positive pole, so that aluminum produces electrochemical corrosion, resulting in the increase of the contact resistance between copper and aluminum.

In addition, due to the great difference between the elastic modulus and thermal expansion coefficient of copper and aluminum, after repeated cold and hot cycles (power on and power off) in operation, a large gap will occur at the contact point, which will affect the contact and also increase the contact resistance. The increase of contact resistance will cause the temperature to rise during operation. At high temperature, corrosion and oxidation will be intensified, resulting in a vicious cycle, which further deteriorates the quality of the connection, and finally leads to the occurrence of accidents such as smoke and burning when the temperature of the contact point is too high.

Question: Why are copper and aluminum wire clips used when connecting copper and aluminum wires?

1. The gray white material generated in the place where the copper wire and aluminum wire are connected is aluminum oxide for a little longer time. The contact resistance at the connection will increase and generate heat, resulting in on-off circuit and easy to cause building fire. So use a special copper – aluminum transition clamp. Avoid unnecessary trouble!

2. If copper wire and aluminum wire are directly hinged together, the joint is easy to oxidize, leading to increased resistance and more likely to burn out. The real reason for this damage is that aluminum is much more active than copper, and many micropotentials (i.e. microbatteries) will be generated on the copper-aluminum bonding surface, which will cause microerosion and increase the contact resistance over time. For ordinary homework, it is more reliable to connect the copper before the tin.

3. In the power system, copper and aluminum are directly connected, and electrochemical corrosion will occur when flowing through the current. Therefore, copper and aluminum should be used for transition, or tin sheets should be placed in the middle of the contact surface, and a layer of conductive paste should be applied when possible. Ordinary family connection, can be linked to copper wire tin aluminum wire, can avoid electrochemical corrosion.

Final conclusion: When the customer chooses the water pump, please look for the copper wire motor. There is a huge difference between the two. The details are as follows:

In fact, it can be summarized into two main points:

I. Price.

The price is undoubtedly cheaper than that of aluminum wire motors. Because of this, in some price wars, the products of aluminum wire motors are more than twice as cheap as those of copper wire motors, which also prompts the mass purchase of middle and low level consumers.

Ii. Quality.

Regardless of the quality of wire performance, service life, copper wire motor is superior to aluminum wire. In addition, in production, the motor embedded aluminum wire due to the quality of brittle, low toughness, easy to break, compared with the same thickness of copper wire qualified rate is lower by 30%.