We are commonly used are super five types of lines or six types of lines, although they are all cable, but the cable material is also divided into several kinds, most of them are in line with the national conditions of production!When buying a line, don’t be a pit!Don’t be greedy for cheap!

First, four iron four aluminum wire

Four iron four aluminum is one of the worst quality cable, transmission quality is poor, it is easy to appear attenuation.Resistance is about 50 Ω 100 m, up to transmit 60 meters.

The differences are as follows:

- Aluminum mesh wire, the inner layer of the wire skin without luster, A pull will be broken.

- The easiest way to do this is to use a magnet to attract the wire. If it is attracted to the wire, it proves that there is iron in it.

- The four wire cores of iron and aluminum are made of different materials. Compared with all copper, materials such as copper-clad aluminum are much harder.

- With fire, the hardness of iron is very high, with fire, will not be soft soon.

Two, copper clad copper wire

Copper coated copper wire refers to the bronze outside and coated with a layer of oxygen free copper, so it is also called bronze wire.This kind of wire is generally ignored by everyone, not many people understand it, the conductor of the bronze wire belongs to the secondary furnace copper, which contains more impurities.Resistance is about 100 meters, around 40 Ω can transfer about 80 meters, the oxidation resistance is strong, long service life.

The resistance of bronze is much higher than that of ordinary copper-aluminum and oxygen-free copper, so the effective propagation distance of copper-bronze is much less than that of copper-aluminum.However, the physical properties of copper is still relatively stable, not easy to oxidize, so the service life is longer, because the surface is plated with a layer of oxygen-free copper, the surface does not see any difference, but with fire, the oxygen-free copper layer on the surface of the copper will soon melt away.Generally speaking, 0.4 all-copper wire can only reach 80 meters, 0.45 all-copper wire can reach 90 meters, and 0.5 all-copper wire can reach 100 meters.

Three, copper coated aluminum wire

Three, copper coated aluminum wire

The material of copper cladding wire is an oxygen-free copper layer on the surface of the copper core of aluminum or aluminum/steel alloy core.Because aluminum conducts electricity less well than copper, the DC resistance of copper-clad aluminum conductors is greater than that of pure copper conductors.If used as a power supply, copper-clad aluminum conductors will incur additional power consumption and a much lower voltage.100 meters would be about 28 Ω resistance, to sell cheap and transmission can be roughly 100 meters, poor oxygen resistance, long service life.The tensile strength of copper-clad aluminum is lower than that of copper conductor.Do not pull the cable body vigorously during use.Why is copper-clad aluminum mesh wire more easily oxidized?Because copper and aluminum are two metals with different electrodes, in a humid environment, copper and aluminum also have a small amount of water vapor containing impurities to form a galvanic cell.Aluminum is the negative electrode, copper is the positive electrode, the metal aluminum is corroded, so it can not be placed in the place of high air humidity.So in the choice of cable, how to see their use is copper aluminum cable?Fire can be used, if the core of the wire is quickly softened (this identification method is very practical), it proves that the copper core of the wire contains aluminum.

Four, high conductivity aluminum mesh wire

High conductivity aluminum wire, its composition is not just copper silver composition, in fact, is a kind of copper aluminum silver alloy of high performance wire, usually also known as copper coated silver.Has a resistance is small, the characteristics of the transmission is far, compared with the copper, iron and aluminum cable, resistance would be about 20 Ω 100 meters, can transmit 120 meters, but the oxygen resistance is poor, life is not long.There are three main kinds of high conductivity aluminum mesh wire: copper coated aluminum mesh wire (aluminum in the middle, the surface is thin oxygen-free copper layer), high conductivity aluminum mesh wire (imported aluminum, copper coated surface), copper coated silver mesh wire (imported aluminum, full copper coated layer)

Five, copper coated silver cable

The main material of copper coated silver wire is imported aluminum, which is higher in purity than copper coated aluminum wire and high conductive aluminum wire. The inner and outer leather is made of new materials.Resistance would be about 15 Ω 100 meters, which can transmit 150-180 meters, but the oxygen resistance is poor, life is not long.Copper coated silver because it can be transmitted far, we can generally be used in ADSL, computer room, supermarket, warehouse such occasions, the general network transmission is no problem.Compared with the copper coated silver wire, the transmission speed is not so long, but it is not far away. It can also be used in supermarkets, warehouses, and families in small and medium-sized areas.There is also a small amount of aluminum in the copper – silver – coated wire, and aluminum is easily oxidized.With four or five years will probably be oxidized, so in the use of choice, to consider this factor.

We can see from the copper core wire skin, generally speaking, all copper wire is the outer new material, and oxygen free copper is inside and outside the new material.You can see from the luster of the leather and cut a section of the leather to see if it can be drawn. The bright luster is the new material, and the new material can be drawn.But now all copper wire also tends to inside and outside the new material, so it can only be used as a basic basis.

You can also use a knife to scratch a surface or cross section:

Oxygen-free copper wire: scrape off the surface of a layer, the color is basically no difference, the cross section color is uniform, no difference.Bronze wire: scratch off a layer of surface, surface and interior color difference, cross section has a little white spots.You can also use fire, copper surface coated with a layer of oxygen-free copper, in the burning process, you will find oxygen-free copper outer layer will melt, and then wipe with paper, will find that the copper core is difficult to change back to the original brass color;And oxygen-free copper does not contain impurities, in the burning process, only the surface oxidation, after wiping with paper, or restore yellow.

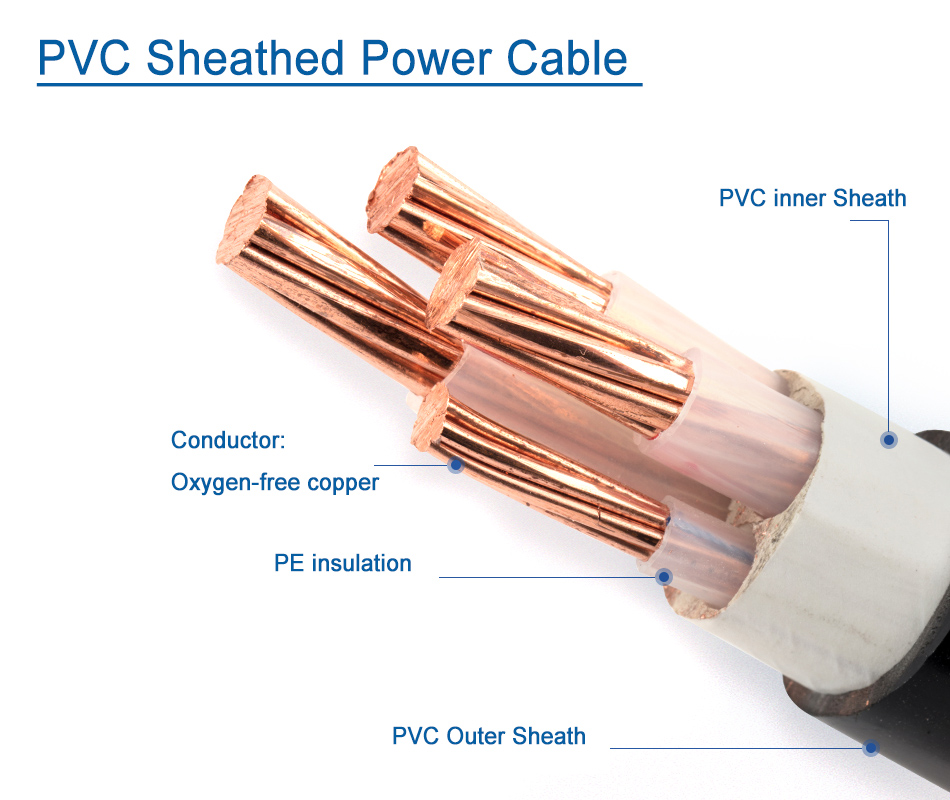

According to the standard, the oxygen content in the oxygen-free copper wire is not more than 0.003%, the total impurity content is not more than 0.05%, and the purity of copper is more than 99.95%.Therefore, oxygen-free copper has high conductivity, good processing performance, welding performance, corrosion resistance and low temperature performance, and is suitable for high quality wire material.Oxygen-free copper cable 10 Ω resistance is about 100 meters of less than, can transfer about 120-150 meters, the signal transmission distance, packet loss rate is low, so in high-definition monitor network engineering, network engineering and home decorating go dark lines are suggested to use oxygen free copper, network stability is guaranteed, the oxidation resistance is strong, long service life.

So here’s the problem:

The above mentioned 6 materials of network cable, two of which have a relatively high transmission distance, theory can transmit about 150 meters, copper coated silver and oxygen free copper, then which one is better?Under normal use environment, the service life of the copper coated silver wire is much shorter than that of the oxygen free copper wire. The antioxidant of the copper coated silver wire is very poor, and the longest can be used for 4-5 years. The oxygen free copper wire can be used for more than 10 years due to its high purity and high antioxidant.When using copper coated silver cable, it should be noted that whether to use copper coated silver or not depends on the service life.

A final note:

Referring to various material cable transmission distance, before mentioned their resistance, cable transmission distance has much to do with the resistance, the smaller the resistance, the smaller the loss, transport the farther the distance, can be seen from the above, oxygen-free copper cable resistance minimum, and resistance to oxidation, it is also the reason why we should choose in the actual project it.