Scope of application

When the PVC insulation cable and sheath layer of the wire and cable have local defects, they are allowed to be repaired, such as broken glue, collapsed pits, disconnections, wrinkles, bumps, ears, edges, breakdown, joints, etc.

Materials and equipment used:

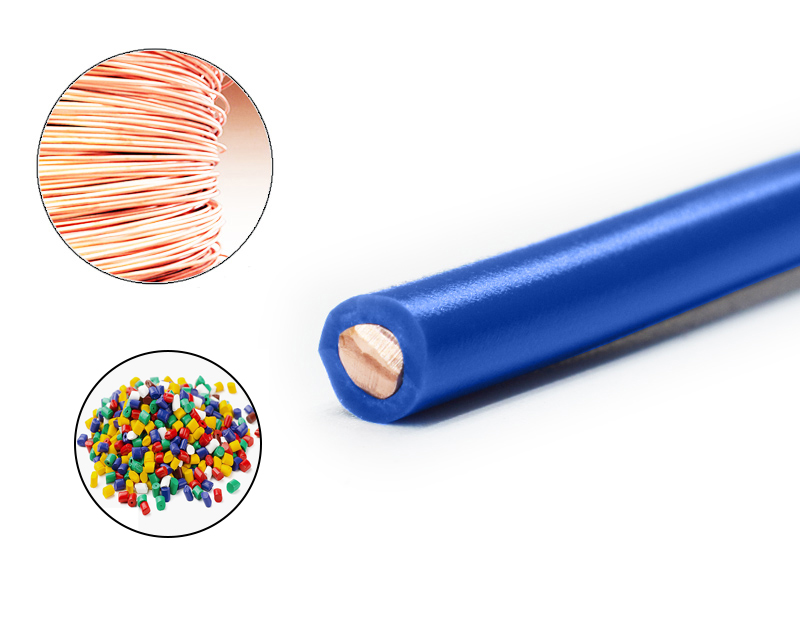

The raw materials use plastic strips, skins, blocks and tubes of the same plastic. The raw materials should be smooth, clean and free of other defects.

The instruments used are fine wooden files, knives, scissors, pliers, screwdrivers, copper sheets or flat and smooth cable paper. The power of hot-air plastic welding torch, electric soldering iron and welding torch for plastic welding is above 300W.

Repair method of local defect

Repair methods such as breakdown points, holes, pits, etc.

Use a knife to trim the defect and cut into a plastic block with a slope of 45° angle and the same size, place it on the repair area, fix it with pliers or a screwdriver, and then use a hot air speed welding gun to continuously weld it, compact and press it with a copper sheet Tighten and flatten. When welding plastic, pay attention to the hot air temperature of the welding gun not to be too high, so as not to burn the plastic in the repaired area. The repaired defect is tested by a spark machine, and it is qualified if it does not break down.

Use a knife to cut the defect of the plastic layer into a slope of 45°, remove the plastic block or strip with the same shape, color and thickness, fix it with pliers or a screwdriver, connect it with a hot air speed welding gun, and then compact it with a copper sheet , Compacted, flattened, and finally tested by spark machine, it is qualified without breakdown.

Scrape the plastic defect flat with a knife, fill in the recessed part with the same plastic strip under the action of a hot-air plastic welding gun, and then flatten, compress and compact the defect repair place with a copper sheet. After the spark machine test, no breakdown Is qualified.

Repair Method of Large joint:

1) Repair of general large joints: cut both sides of the broken glue on the plastic layer along the circumference with a knife.

Take a 45° angle slope, take a clean plastic tube with the same color and thickness, and the same length and outer diameter as the glue break. Cut one side of the tube along the axis to form a 45° angle with each other. Use thin copper cables to tie them at equal distances, then use the same plastic strip to bond and weld them under the hot-air plastic welding gun, and then use copper sheets to compact, compact and flatten. It is qualified if the spark machine does not break down.

2) Repair of large joints in the production process: During the production process, due to other reasons, the temporary stop, the sheath is disconnected, and the joint can be continuous. The method is to cut the plastic sheath into a circular slope with a 45° angle, retreat to the nose, extend into the mold core mouth for 30mm, and then run the glue. After the glue is run, the crew will cooperate with each other and drive the car. Connect the plastic layers by hand, and then reshape and repair.

3) Quality defects appear on the longer length of the PVC sheath power cable from one end, and most of the sheath of the other broken end is good. The length of the cable is fixed, and the repair method of large joints in the production process can also be used. Only after removing the defective end of the sheath, choose a larger mold on the extruder, according to the process, first extrude the end of the sheath, and gradually increase the traction speed to the large joint so that the sheath at the interface gradually It is thinned and covered on the original sheath that is cut into a slope shape, and then reshaped and repaired after the machine is off.