As fire-resistant cables are used more and more widely, many manufacturers are producing them, but their quality is often not guaranteed.

Therefore, in general, enterprises in the development of fire-resistant cable products, are the first trial production of a section of products, sent to the relevant national testing institutions, after obtaining the test report, mass production.

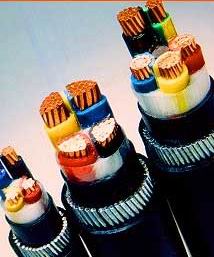

For producing fireproof cables, if refractory test pass rate of 99%, fire-resistant cable, fire-resistant cable is 1% of the security hidden danger, the danger of this is 100% dangerous for users, how to solve these problems we will improve the passing rate of fire-resistant cable fire experiment, from raw material, conductor selection, production process control, etc, to do a description:

1. With three kinds of mica, synthetic mica, phlogopite, white mica, their performance is a synthetic mica best quality, white mica, worst for small specifications of the cable must be selected synthetic mica tape around the package, can not use the mica tape stratification, long-term storage of mica tape is easy to moisture absorption, when stored mica tape so must consider the surrounding environment of temperature and humidity.

2. When selecting mica tape wrapping equipment, good stability should be adopted and the wrapping Angle should be between 300 and 400. The mica tape wrapping equipment should be uniform and tight.

3. For a circular wire core with axial symmetry, its mica tape is tightly wound in all directions, so it is advisable to use a circular compact conductor for the conductor structure of fire-resistant cable. The reasons are as follows:

(1) some users put forward stranded conductor for beam soft conductor structure, which requires enterprises from the aspects of the reliability of the cable to use to communicate with the user to circular press conductor, soft cable structure, the complex ground mica tape damage easily, as a fire-resistant cable conductor is not desirable, but some manufacturer that users need to what kind of fireproof cables, manufacturer should meet the demand of users, I think the user after all relevant details of the cable is not very understand, cable is is closely related to people’s life, so the cable manufacturing enterprises must be related to technical issues with the user clear.

(2) The fan conductor is not suitable for use, because the fan conductor of the mica band winding pressure is not uniform distribution, from the point of view of cost of the fan conductor structure section circumference is greater than the circular conductor section circumference, thus increasing the valuable material mica band, although the circular structure of the cable diameter increased. PVC sheath material increased, but the product material compared with the total cost, the overall cost of circular structure cable is still less.

Based on the above description, from the technical and economic analysis, the circular structure of the conductor of fire-resistant power cable is the best.