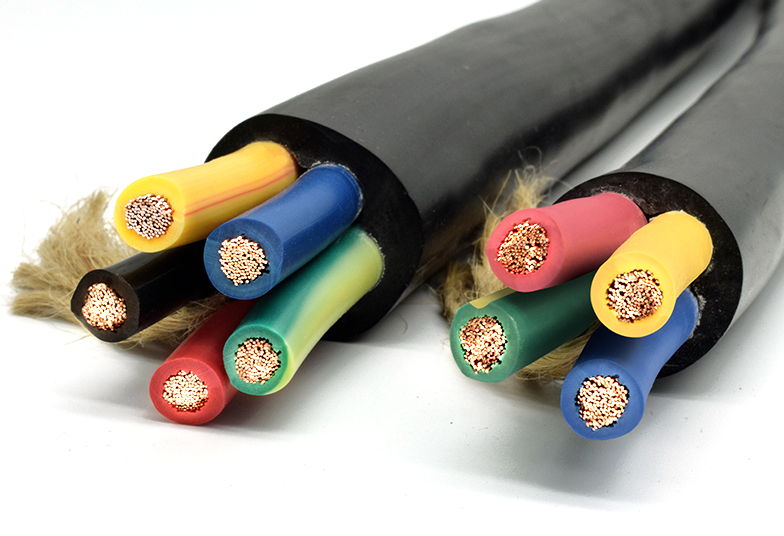

Environmental protection wire refers to the material is environmental protection wire.

The material includes insulating material, conductor material and shielding material. Insulation such as PVC, irradiated cross-linked PVC (XL-PVC), irradiated cross-linked polyethylene (XL-PE), low smoke free (Halogen-free), silicone rubber, Teflon Telflon and so on. The environmental protection of insulation materials is mainly the EU’s RoHS environmental protection directive and the EU’s environmental regulations on children’s toys do not contain 6P (Non-6P), that is, does not contain phthalates. Now the most environmentally friendly is low smoke halogen-free, does not contain halogen elements.

The most common conductor material is copper. Copper has bare copper (brass, red copper), tinned copper, silver-plated copper wire, etc., which are essentially copper, but the surface is plated with other substances. Now there are copper – coated aluminum and copper – coated steel conductors on the market. If the electrical performance requirements are high, copper is the best. The environmental protection of conductors is mainly required to be free of heavy metals (RoHS).

Environmental protection cable means that it does not contain lead, cadmium, hexavalent chromium, mercury and other heavy metals, and does not contain brominated flame retardants. The environmental protection performance of the cable is tested by SGS recognized testing institutions, and it is in line with the European Union Environmental Protection Directive (ROSH) and higher than its index requirements. No harmful halogen gas, no corrosive gas, less fever when burning, no pollution of soil wires and cables.

Main technical indicators:

- Rated voltage: 450/750V and below

- The maximum permissible operating temperature of the conductor shall not exceed 70 ℃, 90 ℃ and 125℃ respectively.

- Cable combustion smoke density in line with GB/T 17651-1998 (equivalent to IEC1043) standard requirements, light transmittance ≥60%.

- Cable halogen acid content test conforms to GB/T 17650-1998 (equivalent to IEC 754-2) standard requirements.

(1) PH ≥4.3

(2) Conductivity ≤10μs/mm

- The flame retardant performance of the cable conforms to the requirements of GB/T 12666-1990.

6.Toxicity index of cable ≤3.