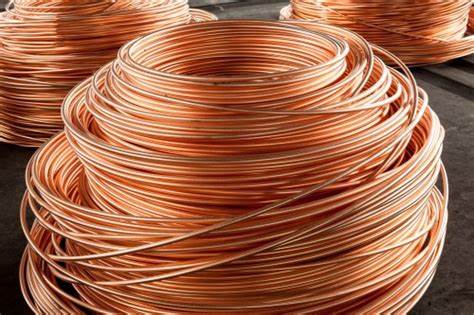

Cable is often used in reality, we can’t tell the difference from the surface, copper wire inside the cable is different, copper rod is the main raw material of the cable industry, there are two main production methods — continuous casting continuous rolling method and up-leading continuous casting method. The oxygen content and appearance of copper rods are different due to different processes. So let’s take a look at the cable copper difference in what aspects.

I. Process defects:

The cable copper is melted while being added. There is no condition for full reduction of the molten copper water. The entire melting process and the copper water production process cannot be separated by oxygen, so the oxygen content is very high. Molten copper fuel is generally a gas, gas combustion process, will directly affect the copper liquefaction branch, the impact of sulfur and hydrogen. When the casting machine crystallizes the copper liquid into a solid, oxygen isolation cannot be carried out, so a second large amount of oxygen is taken during the casting process. Due to a variety of factors, the temperature is not easy to control, the ingot temperature into the mill, the temperature is required to control at 850℃, the greater the deviation, the greater the impact on the quality of copper rod, and a link slightly some problems, will affect the temperature control.

Ii. Technological Advantages:

(1) High output, the average output of small units can reach 10 ~ 14 tons per hour.

(2) The copper rod unloading wire adopts plum-style, which is easy for the wire drawing machine to lay out.

(3) The drawing line is of large weight, generally up to 4 tons per plate.

Low oxygen copper bar grades and characteristics: There are three grades of low oxygen copper bar, T1, T2 and T3. Low oxygen copper bar is hot rolled, so it is soft bar, code name is R.

(1) T1: Use high purity electrolytic copper as raw material (copper content greater than 99.9975%) to produce low oxygen copper rod.

(2) T2: Use 1# electrolytic copper as raw material (copper content greater than 99.95%) to produce hypoxic copper rod.

(3) T3: Use 2# electrolytic copper as raw material (copper content > 99.90%) to produce hypoxic copper rod. Because high pure electrolytic copper and 2# electrolytic copper market is very few, generally use 1# electrolytic copper as raw materials, so the general low oxygen copper bar brand is: T2R.